Page 53 - ChipScale_Jan-Feb_2021-digital

P. 53

structures (Figure 1c), by applying a full

dose at the via and a partial dose for the

redistribution layer (RDL) lines, a single-

exposure process is used without impacting

throughput. The inherent flexibility of

maskless exposure, in conjunction with

the light valve’s ability to modulate the

exposure dose can reduce the number of

process steps required and increase yield

while maintaining throughput.

Dynamic data generation

Direct imaging systems have a wide

range of functions to increase flexibility for

advanced packaging and MEMS fabrication

processes, many of which utilize dynamic data

generation. Consider three different alignment

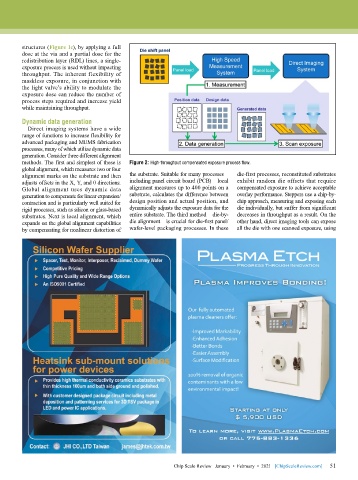

methods. The first and simplest of these is Figure 2: High-throughput compensated exposure process flow.

global alignment, which measures two or four

alignment marks on the substrate and then the substrate. Suitable for many processes – die-first processes, reconstituted substrates

adjusts offsets in the X, Y, and θ directions. including panel circuit board (PCB) – local exhibit random die offsets that require

Global alignment uses dynamic data alignment measures up to 400 points on a compensated exposure to achieve acceptable

generation to compensate for linear expansion/ substrate, calculates the difference between overlay performance. Steppers use a chip-by-

contraction and is particularly well suited for design position and actual position, and chip approach, measuring and exposing each

rigid processes, such as silicon or glass-based dynamically adjusts the exposure data for the die individually, but suffer from significant

substrates. Next is local alignment, which entire substrate. The third method – die-by- decreases in throughput as a result. On the

expands on the global alignment capabilities die alignment – is crucial for die-first panel/ other hand, direct imaging tools can expose

by compensating for nonlinear distortion of wafer-level packaging processes. In these all the die with one scanned exposure, using

51

Chip Scale Review January • February • 2021 [ChipScaleReview.com] 51