Page 48 - ChipScale_Jan-Feb_2021-digital

P. 48

backgrinding (BG), chemical vapor

deposition (CVD), or other chemical

processes. By hardening the adhesive

layer before loading into several

p r o c e s s e s , t he d eg r a d a t io n a nd

softening of the adhesive layer during

these processes can be prevented.

To distinguish this UV irradiation at

405nm for polymerization of the resin

before chemical or thermal processing

from the use of UV irradiation at

254n m for N 2 gas generation, we

refer to the 405 nm-wavelength UV

irradiation as “pre-UV.” By using pre-

UV irradiation, the adhesive got rigid

and the adhesion strength gets lower.

This crosslinking of the adhesive resin

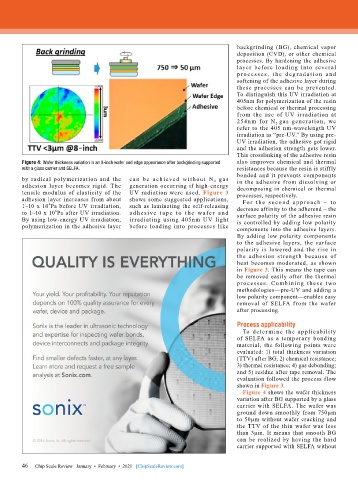

Figure 4: Wafer thickness variation in an 8-inch wafer and edge appearance after backgrinding supported also improves chemical and thermal

with a glass carrier and SELFA. resistances because the resin is stiffly

bonded and it prevents components

by radical polymerization and the ca n be a ch ieve d w it hout N 2 ga s in the adhesive from dissolving or

adhesion layer becomes rigid. The generation occurring if high-energy decomposing in chemical or thermal

tensile modulus of elasticity of the UV radiation were used. Figure 3 processes, respectively.

adhesion layer increases from about shows some suggested applications, For t he s e c ond a p p r o a ch – t o

4

1~10 x 10 Pa before UV irradiation, such as laminating the self-releasing decrease affinity to the adherend – the

6

to 1~10 x 10 Pa after UV irradiation. a d h e sive t a p e t o t h e wa fe r a n d surface polarity of the adhesive resin

By using low-energy UV irradiation, irradiating using 405nm UV light is controlled by adding low polarity

polymerization in the adhesive layer before loading into processes like components into the adhesive layers.

By adding low polarity components

to the adhesive layers, the surface

polarity is lowered and the rise in

the adhesion strength because of

heat becomes moderated, as shown

in Figure 3. This means the tape can

be removed easily after the thermal

processes. Combi ni ng these t wo

methodologies—pre-UV and adding a

low polarity component—enables easy

removal of SELFA from the wafer

after processing.

Process applicability

To deter mine the applicabilit y

of SELFA as a temporary bonding

material, the following points were

evaluated: 1) total thickness variation

(TTV) after BG; 2) chemical resistance;

3) thermal resistance; 4) gas debonding;

and 5) residue after tape removal. The

evaluation followed the process flow

shown in Figure 3.

Figure 4 shows the wafer thickness

variation after BG supported by a glass

carrier with SELFA. The wafer was

ground down smoothly from 750µm

to 50µm without wafer cracking and

the TTV of the thin wafer was less

than 3µm. It means that smooth BG

can be realized by having the hard

carrier supported with SELFA without

46

46 Chip Scale Review January • February • 2021 [ChipScaleReview.com]