Page 46 - ChipScale_Jan-Feb_2021-digital

P. 46

Going beyond traditional temporary bonding materials

By Taro Shiojima, Munehiro Hatai, Minoru Inoue, Ryoichi Watanabe, Toshio Enami, Daihei Sugita

[SEKISUI CHEMICAL CO., LTD.]

H igh-performance computing

(HPC) applications require

not only acceleration of

processing performance speed, but also

reduction of power consumption and a lower

cost structure. To meet those requirements,

3D packaging has recently been developed

for multi-chip heterogeneous applications

using through-silicon via (TSV), wafer on

wafer (WoW), chip on wafer (CoW), and

other technologies [1-5].

It is required that the technologies

noted above stack multi-chips in a

package and bond the chips to chips,

or to wafers, directly [6,7]. For these

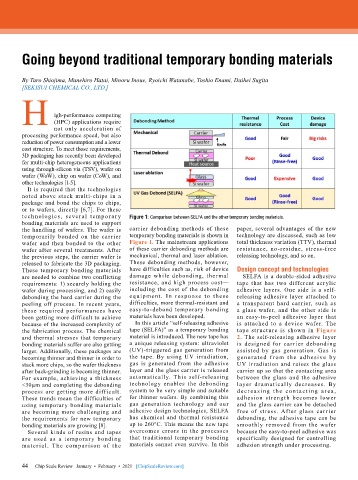

tech nologies, several tempora r y Figure 1: Comparison between SELFA and the other temporary bonding materials.

bonding materials are used to support

the handling of wafers. The wafer is carrier debonding methods of these paper, several advantages of the new

temporarily bonded on the carrier temporary bonding materials is shown in technology are discussed, such as low

wafer and then bonded to the other Figure 1. The mainstream applications total thickness variation (TTV), thermal

wafer after several treatments. After of these carrier debonding methods are resistance, no-residue, stress-free

the previous steps, the carrier wafer is mechanical, thermal and laser ablation. releasing technology, and so on.

released to fabricate the 3D packaging. These debonding methods, however,

These temporary bonding materials have difficulties such as, risk of device Design concept and technologies

are needed to combine two conflicting damage while debonding, thermal SELFA is a double-sided adhesive

requirements: 1) securely holding the resistance, and high process cost— tape that has two different acrylic

wafer during processing, and 2) easily including the cost of the debonding adhesive layers. One side is a self-

debonding the hard carrier during the equipment. I n response to these releasing adhesive layer attached to

peeling off process. In recent years, difficulties, more thermal-resistant and a transparent hard carrier, such as

these required performances have easy-to-debond temporary bonding a glass wafer, and the other side is

been getting more difficult to achieve materials have been developed. an easy-to-peel adhesive layer that

because of the increased complexity of In this article “self-releasing adhesive is attached to a device wafer. The

the fabrication process. The chemical tape (SELFA)” as a temporary bonding tape structure is shown in Figure

and thermal stresses that temporary material is introduced. The new tape has 2. The self-releasing adhesive layer

bonding materials suffer are also getting a unique releasing system: ultraviolet is designed for carrier debonding

larger. Additionally, these packages are (UV)-triggered gas generation from assisted by gas generation. Gas is

becoming thinner and thinner in order to the tape. By using UV irradiation, ge ne r at ed f rom t he a d hesive by

stack more chips, so the wafer thickness gas is generated from the adhesive UV irradiation and raises the glass

after back-grinding is becoming thinner. layer and the glass carrier is released carrier up so that the contacting area

For example, achieving a thickness automatically. This self-releasing between the glass and the adhesive

<30µm and completing the debonding technology enables the debonding layer dramatically decreases. By

process are getting more difficult. system to be very simple and suitable de c re a si ng t he cont a ct i ng a re a ,

These trends mean the difficulties of for thinner wafers. By combining this adhesion strength becomes lower

using temporary bonding materials gas generation technology and our and the glass carrier can be detached

are becoming more challenging and adhesive design technologies, SELFA free of stress. After glass carrier

the requirements for new temporary has chemical and thermal resistance debonding, the adhesive tape can be

bonding materials are growing [8]. up to 260°C. This means the new tape smoothly removed from the wafer

Several kinds of resins and tapes overcomes errors in the processes because the easy-to-peel adhesive was

are used as a temporar y bonding that traditional temporary bonding specifically designed for controlling

mater ial. The compar ison of the materials cannot even survive. In this adhesion strength under processing.

44 Chip Scale Review January • February • 2021 [ChipScaleReview.com]

44