Page 47 - ChipScale_Jan-Feb_2021-digital

P. 47

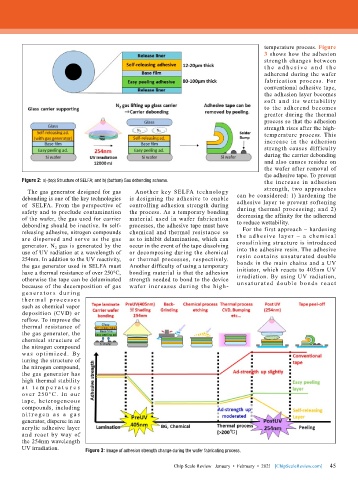

temperature process. Figure

3 shows how the adhesion

strength changes between

t he a d he s i v e a nd t he

adherend during the wafer

fabrication process. For

conventional adhesive tape,

the adhesion layer becomes

sof t a nd its wet t abilit y

to the adherend becomes

greater during the thermal

process so that the adhesion

strength rises after the high-

temperature process. This

increase in the adhesion

strength causes difficulty

during the carrier debonding

and also causes residue on

the wafer after removal of

the adhesive tape. To prevent

Figure 2: a) (top) Structure of SELFA; and b) (bottom) Gas debonding scheme. the increase in adhesion

The gas generator designed for gas Another key SELFA technology strength, two approaches

debonding is one of the key technologies is designing the adhesive to enable can be considered: 1) hardening the

of SELFA. From the perspective of controlling adhesion strength during adhesive layer to prevent softening

safety and to preclude contamination the process. As a temporary bonding during thermal processing; and 2)

of the wafer, the gas used for carrier material used in wafer fabrication decreasing the affinity for the adherend

debonding should be inactive. In self- processes, the adhesive tape must have to reduce wettability.

releasing adhesive, nitrogen compounds chemical and thermal resistance so For the first approach – hardening

are dispersed and serve as the gas as to inhibit delamination, which can t he ad hesive layer – a chem ical

generator. N 2 gas is generated by the occur in the event of the tape dissolving crosslinking structure is introduced

use of UV radiation at a wavelength of or decomposing during the chemical into the adhesive resin. The adhesive

254nm. In addition to the UV reactivity, or thermal processes, respectively. resin contains unsaturated double

the gas generator used in SELFA must Another difficulty of using a temporary bonds in the main chains and a UV

have a thermal resistance of over 250°C, bonding material is that the adhesion initiator, which reacts to 405nm UV

otherwise the tape can be delaminated strength needed to bond to the device irradiation. By using UV radiation,

because of the decomposition of gas wafer increases during the high- u n s at u r at e d double b ond s r e a ct

g e n e r a t o r s d u r i n g

t h e r m a l p ro c e s se s

such as chemical vapor

deposition (CVD) or

reflow. To improve the

thermal resistance of

the gas generator, the

chemical structure of

the nitrogen compound

wa s opt i m i zed. By

tuning the structure of

the nitrogen compound,

the gas generator has

high thermal stability

at t e m p e r at u r e s

over 250°C. I n ou r

tape, heterogeneous

compounds, including

n i t r o g e n a s a g a s

generator, disperse in an

acrylic adhesive layer

and react by way of

the 254nm wavelength

UV irradiation. Figure 3: Image of adhesion strength change during the wafer fabricating process.

45

Chip Scale Review January • February • 2021 [ChipScaleReview.com] 45