Page 49 - ChipScale_Jan-Feb_2021-digital

P. 49

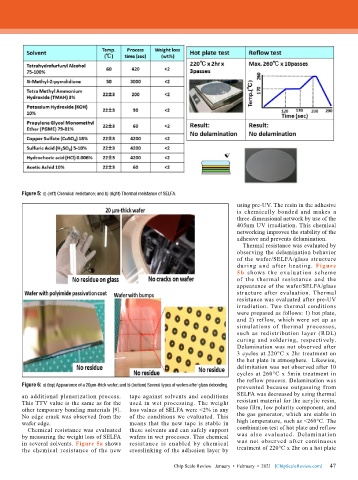

Figure 5: a) (left) Chemical resistance; and b) (right) Thermal resistance of SELFA.

using pre-UV. The resin in the adhesive

is chemically bonded and makes a

three-dimensional network by use of the

405nm UV irradiation. This chemical

networking improves the stability of the

adhesive and prevents delamination.

Thermal resistance was evaluated by

observing the delamination behavior

of the wafer/SELFA/glass structure

during and after heating. Figure

5b shows the evaluation scheme

of the thermal resistance and the

appearance of the wafer/SELFA/glass

structure after evaluation. Thermal

resistance was evaluated after pre-UV

irradiation. Two thermal conditions

were prepared as follows: 1) hot plate,

and 2) reflow, which were set up as

simulations of thermal processes,

such as redistribution layer (RDL)

curing and soldering, respectively.

Delamination was not observed after

3 cycles at 220°C x 2hr treatment on

the hot plate in atmosphere. Likewise,

delimitation was not observed after 10

cycles at 260°C x 5min treatment in

the reflow process. Delamination was

Figure 6: a) (top) Appearance of a 20µm-thick wafer; and b) (bottom) Several types of wafers after glass debonding. prevented because outgassing from

an additional planarization process. tape against solvents and conditions SELFA was decreased by using thermal

This TTV value is the same as for the used in wet processing. The weight resistant material for the acrylic resin,

other temporary bonding materials [9]. loss values of SELFA were <2% in any base film, low polarity component, and

No edge crack was observed from the of the conditions we evaluated. This the gas generator, which are stable in

wafer edge. means that the new tape is stable in high temperature, such as <260°C. The

Chemical resistance was evaluated these solvents and can safely support combination test of hot plate and reflow

by measuring the weight loss of SELFA wafers in wet processes. This chemical was also evaluated. Delamination

in several solvents. Figure 5a shows resistance is enabled by chemical was not observed after continuous

the chemical resistance of the new crosslinking of the adhesion layer by treatment of 220°C x 2hr on a hot plate

47

Chip Scale Review January • February • 2021 [ChipScaleReview.com] 47