Page 43 - ChipScale_Jan-Feb_2021-digital

P. 43

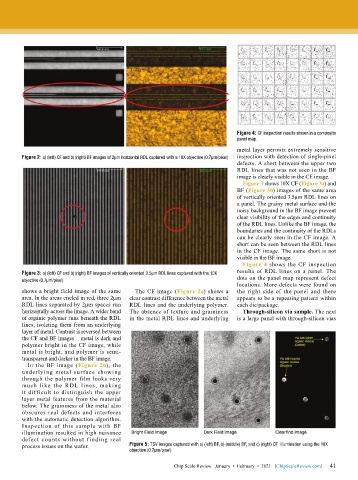

Figure 4: CF inspection results shown in a composite

panel map.

metal layer permits extremely sensitive

Figure 2: a) (left) CF and b) (right) BF images of 2µm horizontal RDL captured with a 10X objective (0.7µm/pixel) inspection with detection of single-pixel

defects. A short between the upper two

RDL lines that was not seen in the BF

image is clearly visible in the CF image.

Figure 3 shows 10X CF (Figure 3a) and

BF (Figure 3b) images of the same area

of vertically oriented 3.5µm RDL lines on

a panel. The grainy metal surface and the

noisy background in the BF image prevent

clear visibility of the edges and continuity

of the RDL lines. Unlike the BF image, the

boundaries and the continuity of the RDLs

can be clearly seen in the CF image. A

short can be seen between the RDL lines

in the CF image. The same short is not

visible in the BF image.

Figure 4 shows the CF inspection

results of RDL lines on a panel. The

Figure 3: a) (left) CF and b) (right) BF images of vertically oriented 3.5µm RDL lines captured with the 10X

objective (0.7µm/pixel) dots on the panel map represent defect

locations. More defects were found on

shows a bright field image of the same The CF image (Figure 2a) shows a the right side of the panel and there

area. In the areas circled in red, three 2µm clear contrast difference between the metal appears to be a repeating pattern within

RDL lines separated by 2µm spaces run RDL lines and the underlying polymer. each die/package.

horizontally across the image. A wider band The absence of texture and graininess Through-silicon via sample. The next

of organic polymer runs beneath the RDL in the metal RDL lines and underlying is a large panel with through-silicon vias

lines, isolating them from an underlying

layer of metal. Contrast is reversed between

the CF and BF images – metal is dark and

polymer bright in the CF image, while

metal is bright, and polymer is semi-

transparent and darker in the BF image.

In the BF image (Figure 2b), the

underlying metal surface showing

through the polymer film looks very

much like the RDL lines, making

it difficult to distinguish the upper

layer metal features from the material

below. The graininess of the metal also

obscures real defects and interferes

with the automatic detection algorithm.

Inspection of this sample with BF

illumination resulted in high nuisance

defect counts without finding real

process issues on the wafer. Figure 5: TSV images captured with a) (left) BF, b) (middle) DF, and c) (right) CF illumination using the 10X

objective (0.7µm/pixel)

41

Chip Scale Review January • February • 2021 [ChipScaleReview.com] 41