Page 56 - ChipScale_Jan-Feb_2021-digital

P. 56

TECHNOLOGY TRENDS

Adhesive bonding for flexible microLED

display assembly

By Goutham Ezhilarasu, Subramanian Iyer [UCLA] Ajit Paranjpe [Veeco Instruments, Inc.]

Jay Lee [DISCO Corporation] Frank Wei [DISCO Hi-Tec America, Inc.]

I n recent years, there has been thickness), sequential pick and place for action of a voltage-driven stamp to attract

growing interest in fabricating high-

assembly is impractical. Therefore, a mass

and pickup microLEDs for transfer. This

resolution information displays using

a large block of devices from the growth

micro-scale inorganic light emitting transfer process is generally used wherein approach is very sensitive to substrate

planarity and surface contamination, and

diodes (i.e., microLEDs) as an alternative substrate are transferred and assembled onto involves a relatively complex process with

to organic LED (OLED) or liquid crystal the target in a massively parallel fashion [2] specialized equipment such as an active

display (LCD) displays. The main reasons (Figure 1). Before releasing from the growth stamp. Approaches based on electromagnetic

for this interest is the remarkable quality of

displays made using microLEDs that possess

several benefits [1]: 1) microLEDs are based

on compound semiconductor material

systems like GaN, GaAs or InP that have

far superior emission properties like sharper

line width, higher quantum efficiencies,

and strong luminance exceeding 10 cd/m ;

6

2

2) Resistant to environmental conditions

such as temperature and humidity due to

their chemical stability leading to longer

operational lifetimes (>100,000 hours); and

3) Ultra-fast response times typically in

the nanosecond range because of the high

mobility of carriers. Such high-quality

microLED displays can have a wide variety

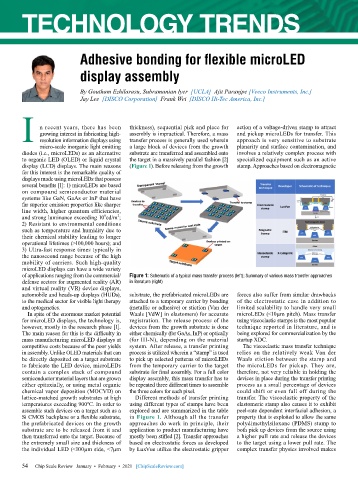

of applications ranging from the commercial/ Figure 1: Schematic of a typical mass transfer process (left); Summary of various mass transfer approaches

defense sectors for augmented reality (AR) in literature (right)

and virtual reality (VR) device displays,

automobile and heads-up displays (HUDs), substrate, the prefabricated microLEDs are forces also suffer from similar drawbacks

to the medical sector for visible light therapy attached to a temporary carrier by bonding of the electrostatic case in addition to

and optogenetics. (metallic or adhesive) or stiction (Van der limited scalability to handle very small

In spite of the enormous market potential Waals [VdW] in elastomers) for accurate microLEDs (<10µm pitch). Mass transfer

for microLED displays, the technology is, registration. The release process of the using viscoelastic stamps is the most popular

however, mostly in the research phase [1]. devices from the growth substrate is done technique reported in literature, and is

The main reason for this is the difficulty in either chemically (for GaAs, InP) or optically being explored for commercialization by the

mass manufacturing microLED displays at (for III-N), depending on the material startup XDC.

competitive costs because of the poor yields system. After release, a transfer printing The viscoelastic mass transfer technique

in assembly. Unlike OLED materials that can process is utilized wherein a “stamp” is used relies on the relatively weak Van der

be directly deposited on a target substrate to pick up selected patterns of microLEDs Waals stiction between the stamp and

to fabricate the LED device, microLEDs from the temporary carrier to the target the microLEDs for pickup. They are,

contain a complex stack of compound substrate for final assembly. For a full color therefore, not very reliable in holding the

semiconductor material layers that are grown display assembly, this mass transfer has to devices in place during the transfer printing

either epitaxially, or using metal organic be repeated three different times to assemble process as a small percentage of devices

chemical vapor deposition (MOCVD) on the three colors for each pixel. could shift or even fall off during the

lattice-matched growth substrates at high Different methods of transfer printing transfer. The viscoelastic property of the

temperatures exceeding 900ºC. In order to using different types of stamps have been elastomeric stamp also causes it to exhibit

assemble such devices on a target such as a explored and are summarized in the table peel-rate dependent interfacial adhesion, a

Si CMOS backplane or a flexible substrate, in Figure 1. Although all the transfer property that is exploited to allow the same

the prefabricated devices on the growth approaches do work in principle, their polydimethylsiloxane (PDMS) stamp to

substrate are to be released from it and application to product manufacturing have both pick up devices from the source using

then transferred onto the target. Because of mostly been stifled [2]. Transfer approaches a higher pull rate and release the devices

the extremely small size and thickness of based on electrostatic forces as developed to the target using a lower pull rate. The

the individual LED (<100µm side, <7µm by LuxVue utilize the electrostatic gripper complex transfer physics involved makes

54

54 Chip Scale Review January • February • 2021 [ChipScaleReview.com]