Page 36 - Chip Scale Review_March-April_2024-digital

P. 36

the bond tool and pre-heated to 100°C

to reduce the interposer warpage.

Subsequently, the RDL interposer

was aligned and gently pressed onto

the organic substrate with a low bond

force. The bond tool was then heated

to a peak bond temperature of 300°C

for a short duration and subsequently

cooled down. During the cooling

phase, the bond force was maintained

to minimize the warpage of the RDL

interposer. Figure 11c shows the RDL

interposer successfully assembled

to the organic substrate with the

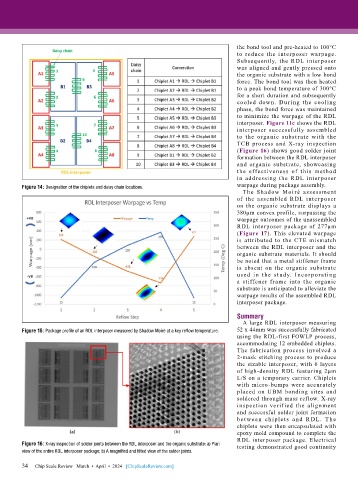

TCB process and X-ray inspection

(Figure 16) shows good solder joint

formation between the RDL interposer

and organic substrate, showcasing

the effectiveness of this method

in addressing the RDL interposer

Figure 14: Designation of the chiplets and daisy chain locations. warpage during package assembly.

T he Shadow Moiré assessment

of the assembled RDL inter poser

on the organic substrate displays a

380µm convex profile, surpassing the

warpage outcomes of the unassembled

RDL interposer package of 277µm

(Figure 17). This elevated warpage

is attributed to the CTE mismatch

between the RDL interposer and the

organic substrate materials. It should

be noted that a metal stiffener frame

is absent on the organic substrate

used in the st udy. Incor porating

a stiffener frame into the organic

substrate is anticipated to alleviate the

warpage results of the assembled RDL

interposer package.

Summary

A large RDL interposer measuring

Figure 15: Package profile of an RDL interposer measured by Shadow Moiré at a key reflow temperature. 52 x 44mm was successfully fabricated

using the RDL-first FOWLP process,

accommodating 12 embedded chiplets.

The fabrication process involved a

2-mask stitching process to produce

the sizable interposer, with 6 layers

of high-density RDL featuring 2µm

L/S on a temporary carrier. Chiplets

with micro-bumps were accurately

placed on UBM bonding sites and

soldered through mass reflow. X-ray

inspection verified the alignment

and successful solder joint formation

bet ween ch iplet s a nd R DL. T he

chiplets were then encapsulated with

epoxy mold compound to complete the

RDL interposer package. Electrical

Figure 16: X-ray inspection of solder joints between the RDL interposer and the organic substrate: a) Plan testing demonstrated good continuity

view of the entire RDL interposer package; b) A magnified and tilted view of the solder joints.

34

34 Chip Scale Review March • April • 2024 [ChipScaleReview.com]