Page 34 - Chip Scale Review_March-April_2024-digital

P. 34

Meander comb test structure at whe r e t he t wo t r a ce s c onve rge.

the stitch line. Figure 12 shows a Additionally, Figure 13a presents

2µm line/space meander comb test the I-V curve of the meander trace,

structure positioned at the stitch line demonstrating good connectivity for

between the two masks in the field. A the stitched Cu traces. The measured

slight taper is visible at the junction i n t r a - l a y e r l e a k a g e c u r r e n t i s

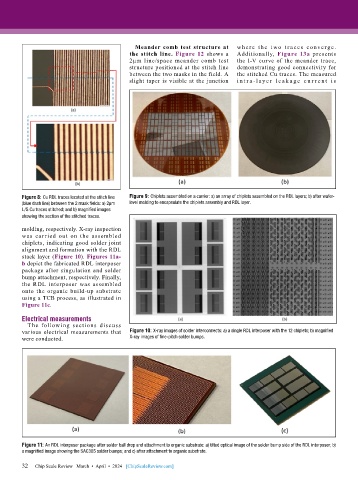

Figure 8: Cu RDL traces located at the stitch line Figure 9: Chiplets assembled on a carrier: a) an array of chiplets assembled on the RDL layers; b) after wafer-

(blue dash line) between the 2 mask fields: a) 2µm level molding to encapsulate the chiplets assembly and RDL layer.

L/S Cu traces stitched; and b) magnified images

showing the section of the stitched traces.

molding, respectively. X-ray inspection

was carried out on the assembled

chiplets, indicating good solder joint

alignment and formation with the RDL

stack layer (Figure 10). Figures 11a-

b depict the fabricated RDL interposer

package after singulation and solder

bump attachment, respectively. Finally,

the RDL interposer was assembled

onto the organic build-up substrate

using a TCB process, as illustrated in

Figure 11c.

Electrical measurements

The following sections discuss

various electrical measurements that Figure 10: X-ray images of solder interconnects: a) a single RDL interposer with the 12 chiplets; b) magnified

were conducted. X-ray images of fine-pitch solder bumps.

Figure 11: An RDL interposer package after solder ball drop and attachment to organic substrate: a) tilted optical image of the solder bump side of the RDL interposer; b)

a magnified image showing the SAC305 solder bumps; and c) after attachment to organic substrate.

32 Chip Scale Review March • April • 2024 [ChipScaleReview.com]

32