Page 31 - Chip Scale Review_March-April_2024-digital

P. 31

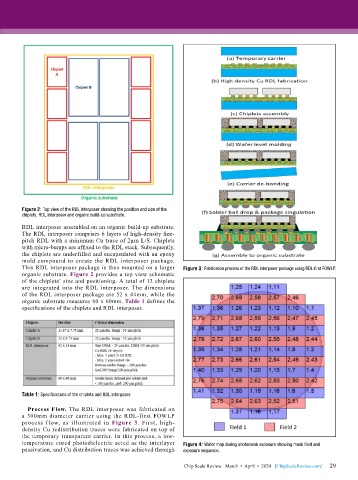

Figure 2: Top view of the RDL interposer showing the position and size of the

chiplets, RDL interposer and organic build-up substrate.

RDL interposer assembled on an organic build-up substrate.

The RDL interposer comprises 6 layers of high-density fine-

pitch RDL with a minimum Cu trace of 2µm L/S. Chiplets

with micro-bumps are affixed to the RDL stack. Subsequently,

the chiplets are underfilled and encapsulated with an epoxy

mold compound to create the RDL interposer package.

This RDL interposer package is then mounted on a larger Figure 3: Fabrication process of the RDL interposer package using RDL-first FOWLP.

organic substrate. Figure 2 provides a top view schematic

of the chiplets’ size and positioning. A total of 12 chiplets

are integrated into the RDL interposer. The dimensions

of the RDL interposer package are 52 x 44mm, while the

organic substrate measures 60 x 60mm. Table 1 defines the

specifications of the chiplets and RDL interposer.

Table 1: Specifications of the chiplets and RDL interposer.

Process Flow. The RDL interposer was fabricated on

a 300mm diameter carrier using the RDL-first FOWLP

process f low, as illustrated in Figure 3. First, high-

density Cu redistribution traces were fabricated on top of

the temporary transparent carrier. In this process, a low-

temperature cured photodielectric acted as the interlayer Figure 4: Wafer map during photomask exposure showing mask field and

passivation, and Cu distribution traces was achieved through exposure sequence.

29

Chip Scale Review March • April • 2024 [ChipScaleReview.com] 29