Page 44 - Chip Scale Review_January-February_2024-digital

P. 44

Results and discussion

The sections below discuss the precise

bond energy measurement done by DCB

and by NI.

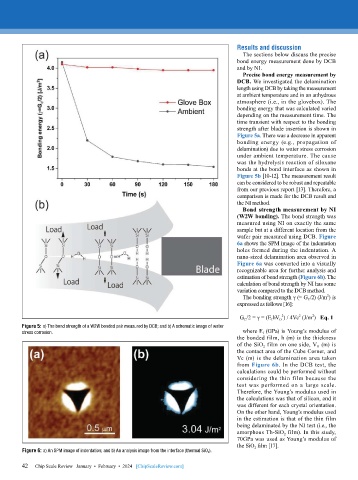

Precise bond energy measurement by

DCB. We investigated the delamination

length using DCB by taking the measurement

at ambient temperature and in an anhydrous

atmosphere (i.e., in the glovebox). The

bonding energy that was calculated varied

depending on the measurement time. The

time transient with respect to the bonding

strength after blade insertion is shown in

Figure 5a. There was a decrease in apparent

bonding energy (e.g., propagation of

delamination) due to water stress corrosion

under ambient temperature. The cause

was the hydrolysis reaction of siloxane

bonds at the bond interface as shown in

Figure 5b [10-12]. The measurement result

can be considered to be robust and repeatable

from our previous report [13]. Therefore, a

comparison is made for the DCB result and

the NI method.

Bond strength measurement by NI

(W2W bonding). The bond strength was

measured using NI on exactly the same

sample but at a different location from the

wafer pair measured using DCB. Figure

6a shows the SPM image of the indentation

holes formed during the indentation. A

nano-sized delamination area observed in

Figure 6a was converted into a visually

recognizable area for further analysis and

estimation of bond strength (Figure 6b). The

calculation of bond strength by NI has some

variation compared to the DCB method.

The bonding strength γ (= G C /2) (J/m ) is

2

expressed as follows [16]:

G C /2 = γ = (E f hV O ) / 4Vc (J/m ) Eq. 1

2

2

2

Figure 5: a) The bond strength of a W2W bonded pair measured by DCB; and b) A schematic image of water

stress corrosion. where E f (GPa) is Young’s modulus of

the bonded film, h (m) is the thickness

of the SiO 2 film on one side, V O (m) is

the contact area of the Cube Corner, and

Vc (m) is the delamination area taken

from Figure 6b. In the DCB test, the

calculations could be performed without

considering the thin film because the

test was performed on a large scale.

Therefore, the Young’s modulus used in

the calculations was that of silicon, and it

was different for each crystal orientation.

On the other hand, Young’s modulus used

in the estimation is that of the thin film

being delaminated by the NI test (i.e., the

amorphous Th-SiO 2 film). In this study,

70GPa was used as Young’s modulus of

the SiO 2 film [17].

Figure 6: a) An SPM image of indentation; and b) An analysis image from the interface (thermal SiO 2 ).

42

42 Chip Scale Review January • February • 2024 [ChipScaleReview.com]