Page 41 - Chip Scale Review_January-February_2024-digital

P. 41

Exploring bond strength for an advanced chiplet with

hybrid bonding

By Junya Fuse, Tomoya Iwata, Yuki Yoshihara, Marie Sano, Fumihiro Inoue [YOKOHAMA National University]

B ecause of the high demand

for high-density vertical

intercon nections using

advanced chiplet technology, hybrid

bonding is now being comprehensively

investigated as an alternative to micro-

bumps. However, there are many

obstacles and challenges in the R&D

phase that remain to be overcome with

respect to die-level hybrid bonding.

For example, a bonding st rength

measurement method for die-level

hybrid bonding has not yet been well

established. Therefore, the bonding

strength measurement method at the die

level was studied using the Cube Corner

indentation method. The validity of the

nanoindentation test was demonstrated

by comparing the bonding strength

calculated by using double-cantilever-

beam and nanoindentation tests. Then,

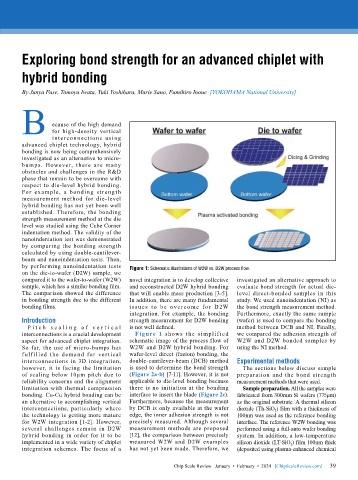

by performing nanoindentation tests Figure 1: Schematic illustrations of W2W vs. D2W process flow.

on the die-to-wafer (D2W) sample, we

compared it to the wafer-to-wafer (W2W) novel integration is to develop collective investigated an alternative approach to

sample, which has a similar bonding film. and reconstructed D2W hybrid bonding evaluate bond strength for actual die-

The comparison showed the difference that will enable mass production [3-5]. level direct-bonded samples in this

in bonding strength due to the different In addition, there are many fundamental study. We used nanoindentation (NI) as

bonding films. issue s t o b e ove rcome for D2W the bond strength measurement method.

integration. For example, the bonding Furthermore, exactly the same sample

Introduction strength measurement for D2W bonding (wafer) is used to compare the bonding

P i t c h s c a l i n g o f v e r t i c a l is not well defined. method between DCB and NI. Finally,

interconnections is a crucial development Figure 1 shows the simplif ied we compared the adhesion strength of

aspect for advanced chiplet integration. schematic image of the process flow of W2W and D2W bonded samples by

So far, the use of micro-bumps has W2W and D2W hybrid bonding. For using the NI method.

f ulf illed the demand for ver tical wafer-level direct (fusion) bonding, the

interconnections in 3D integration, double-cantilever-beam (DCB) method Experimental methods

however, it is facing the limitation is used to determine the bond strength The sections below discuss sample

of scaling below 10μm pitch due to (Figure 2a-b) [7-11]. However, it is not preparation and the bond strength

reliability concerns and the alignment applicable to die-level bonding because measurement methods that were used.

limitation with thermal compression there is no initiation at the bonding Sample preparation. All the samples were

bonding. Cu-Cu hybrid bonding can be interface to insert the blade (Figure 2c). fabricated from 300mm Si wafers (775μm)

an alternative to accomplishing vertical Furthermore, because the measurement as the original substrate. A thermal silicon

interconnections, particularly where by DCB is only available at the wafer dioxide (Th-SiO 2 ) film with a thickness of

the technology is getting more mature edge, the inner adhesion strength is not 100nm was used as the reference bonding

for W2W integration [1-2]. However, precisely measured. Although several interface. The reference W2W bonding was

several challenges remain in D2W measurement methods are proposed performed using a full-auto wafer bonding

hybrid bonding in order for it to be [12], the comparison between precisely system. In addition, a low-temperature

implemented in a wide variety of chiplet measured W2W and D2W examples silicon dioxide (LT-SiO 2 ) film 100nm thick

integration schemes. The focus of a has not yet been made. Therefore, we (deposited using plasma-enhanced chemical

39

Chip Scale Review January • February • 2024 [ChipScaleReview.com] 39