Page 40 - ChipScale_Mar-Apr_2020-digital

P. 40

the test pads and wafer fabrications

features into a subset of the wafer.

Blading enables a die loss and product

cost increase, but eliminates many

modules from the dicing streets.

Removing the modules creates a

clean area for cutting and loading that

improves problems associated with

mechanical dicing. There are other

complications that interact, such as

films used, and wire bond versus a

bumped device, but the major items

discussed here are the driving reasons

for mechanical dicing complications.

Packaging requirements and

interactions

Now that we have covered wafer fab

complications, let’s now move on to

Figure 3: Probe pad example. packaging requirements and interactions,

wafer dicing challenges associated with

package type, and finally, interaction

with scribe structures that need to be

considered during the design phase.

For example, if your device is for the

automotive market, you should consider

asking the following questions: Does it

have burn-in? Is the package prone to high

stress? Knowing your end customer’s

requirements and asking these questions

are normally considered during a design

phase review. However, many times parts

are multi-purposed and can be sold across

many different package types, families and

end user types. This situation complicates

the process further. Don’t panic if you are

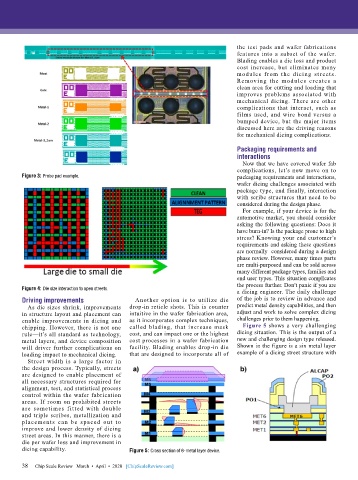

Figure 4: Die size interaction to open streets.

a dicing engineer. The daily challenge

Driving improvements Another option is to utilize die of the job is to review in advance and

As die sizes shrink, improvements drop-in reticle shots. This is counter predict metal density capabilities, and then

in structure layout and placement can intuitive in the wafer fabrication area, adjust and work to solve complex dicing

enable improvements in dicing and as it incorporates complex techniques, challenges prior to them happening.

chipping. However, there is not one called blading, that increase mask Figure 5 shows a very challenging

rule—it’s all standard as technology, cost, and can impact one or the highest dicing situation. This is the output of a

metal layers, and device composition cost processes in a wafer fabrication new and challenging design type released.

will driver further complications on facility. Blading enables drop-in die Shown in the figure is a six metal layer

loading impact to mechanical dicing. that are designed to incorporate all of example of a dicing street structure with

Street width is a large factor in

the design process. Typically, streets

are designed to enable placement of

all necessary structures required for

alignment, test, and statistical process

control within the wafer fabrication

areas. If room on prohibited streets

are sometimes f itted with double

and triple scribes, metallization and

placements can be spaced out to

improve and lower density of dicing

street areas. In this manner, there is a

die per wafer loss and improvement in

dicing capability. Figure 5: Cross section of 6-metal layer device.

38

38 Chip Scale Review March • April • 2020 [ChipScaleReview.com]