Page 42 - ChipScale_Sep-Oct_2020-digital

P. 42

Figure 6: A 30mm die-to-die bonded assembly.

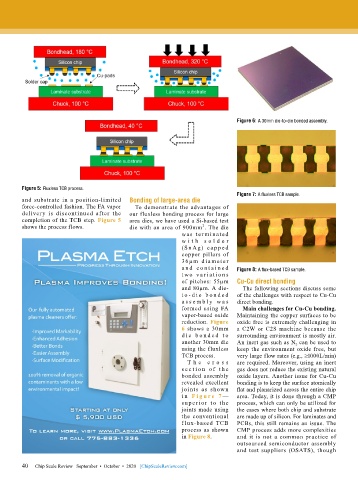

Figure 5: Fluxless TCB process.

Figure 7: A fluxless TCB sample.

and substrate in a position-limited Bonding of large-area die

force-controlled fashion. The FA vapor To demonstrate the advantages of

delivery is discontinued after the our fluxless bonding process for large

completion of the TCB step. Figure 5 area dies, we have used a Si-based test

shows the process flows. die with an area of 900mm . The die

2

was ter m i nated

w i t h s o ld e r

(S n A g) c a p p e d

copper pillars of

36µ m d ia me t e r

a n d co n t ai n e d Figure 8: A flux-based TCB sample.

t wo v a r i at i o n s

of pitches: 55µm Cu-Cu direct bonding

and 80µm. A die- The following sections discuss some

to - d i e b o n d e d of the challenges with respect to Cu-Cu

as s e m b l y w as direct bonding.

formed using FA Main challenges for Cu-Cu bonding.

vapor-based oxide Maintaining the copper surfaces to be

reduction. Figure oxide free is extremely challenging in

6 shows a 30mm a C2W or C2S machine because the

d i e b o n d e d t o surrounding environment is mostly air.

another 30mm die An inert gas such as N 2 can be used to

using the fluxless keep the environment oxide free, but

TCB process. very large flow rates (e.g., ≥1000L/min)

T h e c r o s s are required. Moreover, using an inert

s e c t i o n o f t h e gas does not reduce the existing natural

bonded assembly oxide layers. Another issue for Cu-Cu

revealed excellent bonding is to keep the surface atomically

joints as shown flat and planarized across the entire chip

i n F i g u r e 7 — area. Today, it is done through a CMP

s up e r ior t o t he process, which can only be utilized for

joints made using the cases where both chip and substrate

the conventional are made up of silicon. For laminates and

f lux-based TCB PCBs, this still remains an issue. The

process as shown CMP process adds more complexities

in Figure 8. and it is not a common practice of

outsourced semiconductor assembly

and test suppliers (OSATS), though

40

40 Chip Scale Review September • October • 2020 [ChipScaleReview.com]