Page 41 - ChipScale_Sep-Oct_2020-digital

P. 41

Formic acid reduction mechanism. oxide layers on solder and metal

The chemical reactions through which surfaces prior to and/or during the TCB

formic acid vapor reduces the Sn or Cu process. The middle channel serves as

surface are given in (1), (2) and [11-13]. an exhaust collection port for residual

FA vapor and other gaseous reaction

byproducts. The outermost channel

provides the shielding N 2 gas around

the shroud. This helps to maximize the

FA in vapor form reacts with the containment of residual FA vapor and

tin oxide and leaves a thin layer of tin other reaction by-products under the

formate. This formate layer covers the shroud area. The escaped FA vapors,

bare solder surface and is subsequently inside the machine environment,

r e move d by r a i si ng t he s u r fa c e are ultimately expelled through the Figure 2: A bond head shroud.

temperature above 150°C. A very similar facility-provided exhaust system,

chemical reaction also happens for the which, along with the FA concentration

copper oxide reduction process [5]. inside the machine, is continuously

Formic acid vapor delivery system monitored for safety reasons.

and shroud. The schematic of a FA The f low rates of the shielding

delivery system is shown in Figure 1. g a s , va c uu m , a nd FA vap or a r e

The FA vapor is generated by passing an optimized to maximize the formic

inert carrier (N 2 : nitrogen) gas through acid concentration over the desired

a bubbler containing for mic acid region while simultaneously reducing

(HCOOH ≥95%) solution. Depending the inclusion of oxygen. The shroud

on the bubbler temperature, the N 2 gas design is based on verification of the

coming out is completely saturated with computational fluid dynamics (CFD)-

formic acid, e.g., 3.5% FA, 96.5% N 2 at based gas flow simulations and the

22°C, which is ultimately transferred to experiments. Figure 4 shows a CFD

a shroud mounted onto the bond head simulation of the saturated FA vapor

as shown in Figures 2 and 3. mass fraction over the die region under Figure 3: Shroud mounted on the bond head.

The FA delivery system is designed operating conditions.

to alter the percentage of FA vapor in Process f low for f luxless TCB.

the carrier gas by further diluting it The bond head, carrying the die, is

with N 2 gas. The existing bond heads aligned with the target substrate, which

on current C2W and C2S machines is usually kept at 80-120°C. Then, it

have been modified to include a shroud. is brought to a specified separation

The shroud consists of three channels distance between the chip and the

as shown in Figure 1. The innermost substrate, which ensures the creation

channel supplies FA vapor that reduces of an effective FA mini-environment.

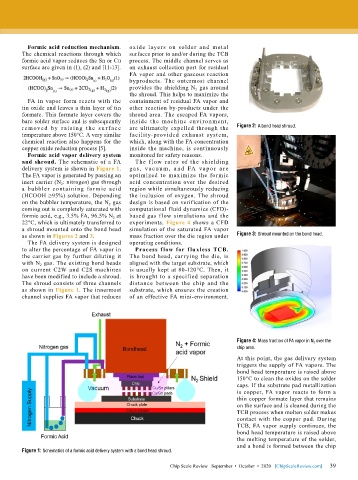

Figure 4: Mass fraction of FA vapor in N 2 over the

chip area.

At this point, the gas delivery system

triggers the supply of FA vapors. The

bond head temperature is raised above

150°C to clean the oxides on the solder

caps. If the substrate pad metallization

is copper, FA vapor reacts to form a

thin copper formate layer that remains

on the surface and is cleaned during the

TCB process when molten solder makes

contact with the copper pad. During

TCB, FA vapor supply continues, the

bond head temperature is raised above

the melting temperature of the solder,

and a bond is formed between the chip

Figure 1: Schematics of a formic acid delivery system with a bond head shroud.

39

Chip Scale Review September • October • 2020 [ChipScaleReview.com] 39