Page 35 - ChipScale_May-June_2020-digital

P. 35

Other costs of quality

A more practical example for yield

monitoring would be a case where a few

months term run at a factory led to partial

voiding in one of the device interfaces in a

run of a few thousand devices. Electrically,

these devices pass, and some will pass a

stress test. After longer periods of time,

however, these devices fail. Because it was

unmonitored, and concentrated, a number

of devices will need to be pulled, repaired,

and a recall issued for items at risk. Even a

100ppm failure rate on average can lead to

an expenditure of $20M or more, depending

on the cost of repair or recall.

The costs of quality go beyond the

simple calculation of recalls and returns.

There are also development cost,

reputation, product delays, returns (and

expedition), and time delays on future

programs. Quality costs are paid for a very

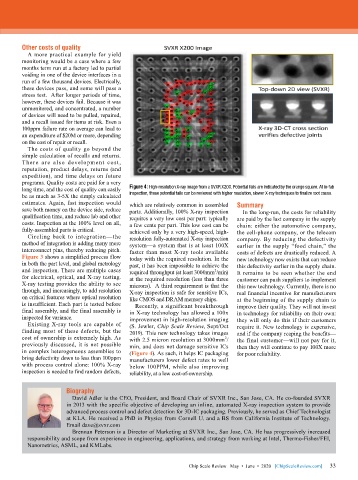

long time, and the cost of quality can easily Figure 4: High-resolution X-ray image from a SVXR X200. Potential fails are indicated by the orange square. At in-fab

be as much as 3-5X the simply calculated inspection, these potential fails can be reviewed with higher resolution, slower X-ray techniques to finalize root cause.

estimates. Again, fast inspection would which are relatively common in assembled Summary

save both money on the device side, reduce parts. Additionally, 100% X-ray inspection In the long-run, the costs for reliability

qualification time, and reduce lab and other requires a very low cost per part: typically are paid by the last company in the supply

costs. Inspection at the 100% level on all, a few cents per part. This low cost can be chain: either the automotive company,

fully-assembled parts is critical. achieved only by a very high-speed, high- the cell-phone company, or the telecom

Circling back to integration—the resolution fully-automated X-ray inspection company. By reducing the defectivity

method of integration is adding many more system—a system that is at least 100X earlier in the supply “food chain,” the

interconnect pins, thereby reducing pitch. faster than most X-ray tools available costs of defects are drastically reduced. A

Figure 3 shows a simplified process flow today with the required resolution. In the new technology now exists that can reduce

in both the part level, and global metrology past, it has been impossible to achieve the this defectivity earlier in the supply chain.

and inspection. There are multiple cases required throughput (at least 3000mm /min) It remains to be seen whether the end

2

for electrical, optical, and X-ray testing. at the required resolution (less than three customer can push suppliers to implement

X-ray testing provides the ability to see microns). A third requirement is that the this new technology. Currently, there is no

through, and increasingly, to add resolution X-ray inspection is safe for sensitive ICs, real financial incentive for manufacturers

on critical features where optical resolution like CMOS and DRAM memory chips. at the beginning of the supply chain to

is insufficient. Each part is tested before Recently, a significant breakthrough improve their quality. They will not invest

final assembly, and the final assembly is in X-ray technology has allowed a 100x in technology for reliability on their own:

inspected for variance. improvement in high-resolution imaging they will only do this if their customers

Existing X-ray tools are capable of (S. Jewler, Chip Scale Review, Sept/Oct require it. New technology is expensive,

finding most of these defects, but the 2019). This new technology takes images and if the company reaping the benefits—

cost of ownership is extremely high. As with 2.5 micron resolution at 3000mm / the final customer—will not pay for it,

2

previously discussed, it is not possible min, and does not damage sensitive ICs then they will continue to pay 100X more

in complex heterogeneous assemblies to (Figure 4). As such, it helps IC packaging for poor reliability.

bring defectivity down to less than 100ppm manufacturers lower defect rates to well

with process control alone: 100% X-ray below 100PPM, while also improving

inspection is needed to find random defects, reliability, at a low cost-of-ownership.

Biography

David Adler is the CEO, President, and Board Chair of SVXR Inc., San Jose, CA. He co-founded SVXR

in 2013 with the specific objective of developing an inline, automated X-ray inspection system to provide

advanced process control and defect detection for 3D-IC packaging. Previously, he served as Chief Technologist

at KLA. He received a PhD in Physics from Cornell U. and a BS from California Institute of Technology.

Email dave@svxr.com

Brennan Peterson is a Director of Marketing at SVXR Inc., San Jose, CA. He has progressively increased

responsibility and scope from experience in engineering, applications, and strategy from working at Intel, Thermo-Fisher/FEI,

Nanometrics, ASML, and KMLabs.

33

Chip Scale Review May • June • 2020 [ChipScaleReview.com] 33