Page 46 - Chip Scale Review_September-October_2023-digital

P. 46

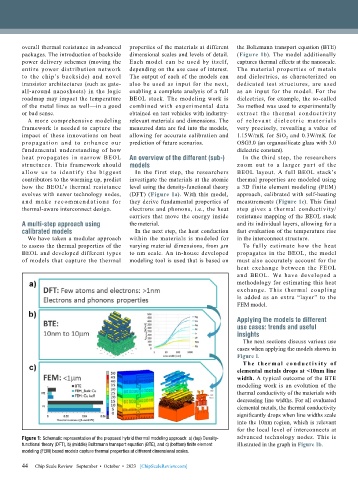

overall thermal resistance in advanced properties of the materials at different the Boltzmann transport equation (BTE)

packages. The introduction of backside dimensional scales and levels of detail. (Figure 1b). The model additionally

power delivery schemes (moving the Each model can be used by itself, captures thermal effects at the nanoscale.

entire power distribution network depending on the use case of interest. The material properties of metals

to the chip’s backside) and novel The output of each of the models can and dielectrics, as characterized on

transistor architectures (such as gate- also be used as input for the next, dedicated test structures, are used

all-around nanosheets) in the logic enabling a complete analysis of a full as an input for the model. For the

roadmap may impact the temperature BEOL stack. The modeling work is dielectrics, for example, the so-called

of the metal lines as well—in a good combined with experimental data 3ω method was used to experimentally

or bad sense. obtained on test vehicles with industry- ext ract the ther mal conductivit y

A more comprehensive modeling relevant materials and dimensions. The of r eleva nt d iele ct r ic m at e r ia l s

framework is needed to capture the measured data are fed into the models, very precisely, revealing a value of

impact of these innovations on heat allowing for accurate calibration and 1.15W/mK for SiO 2 and 0.3W/mK for

propagat ion a nd to en ha nce ou r prediction of future scenarios. OSG3.0 (an organosilicate glass with 3.0

fundamental understanding of how dielectric constant).

heat propagates in nar row BEOL An overview of the different (sub-) In the third step, the researchers

structures. This framework should models zoom out to a larger par t of the

allow us to ident if y t he biggest In the first step, the researchers BEOL layout. A full BEOL stack’s

contributors to the warming up, predict investigate the materials at the atomic thermal properties are modeled using

how the BEOL’s thermal resistance level using the density-functional theory a 3D finite element modeling (FEM)

evolves with newer technology nodes, (DFT) (Figure 1a). With this model, approach, calibrated with self-heating

a nd m a ke r e c om me nd at ion s for they derive fundamental properties of measurements (Figure 1c). This final

thermal-aware interconnect design. electrons and phonons, i.e., the heat step gives a thermal conductivity/

carriers that move the energy inside resistance mapping of the BEOL stack

A multi-step approach using the material. and its individual layers, allowing for a

calibrated models In the next step, the heat conduction fast evaluation of the temperature rise

We have taken a modular approach within the materials is modeled for in the interconnect structure.

to assess the thermal properties of the varying material dimensions, from µm To f ully estimate how the heat

BEOL and developed different types to nm scale. An in-house developed propagates in the BEOL, the model

of models that capture the thermal modeling tool is used that is based on must also accurately account for the

heat exchange between the FEOL

and BEOL. We have developed a

methodology for estimating this heat

exchange. This ther mal coupling

is added as an extra “layer” to the

FEM model.

Applying the models to different

use cases: trends and useful

insights

The next sections discuss various use

cases when applying the models shown in

Figure 1.

T he ther ma l conduc t i v it y of

elemental metals drops at <10nm line

width. A typical outcome of the BTE

modeling work is an evolution of the

thermal conductivity of the materials with

decreasing line widths. For all evaluated

elemental metals, the thermal conductivity

significantly drops when line widths scale

into the 10nm region, which is relevant

for the local level of interconnects at

Figure 1: Schematic representation of the proposed hybrid thermal modeling approach: a) (top) Density- advanced technology nodes. This is

functional theory (DFT), b) (middle) Boltzmann transport equation (BTE), and c) (bottom) finite element illustrated in the graph in Figure 1b.

modeling (FEM) based models capture thermal properties at different dimensional scales.

44

44 Chip Scale Review September • October • 2023 [ChipScaleReview.com]