Page 50 - ChipScale_Mar-Apr_2020-digital

P. 50

Process characterization: design

of experiments

Since early 2016, numerous studies

have been conducted on actual packages

to makes sure that LAB data does

indeed indicate a substantial benefit

over standard MR and TCB processes

before ramping into mass production.

In terms of the assembly process, there

is no difference between MR and LAB

except that the MR reflow process is

interchanged with LAB (Figure 7). Both

capillary underfill (CUF) and molded

underfill (MUF) can be used in the

Figure 5: IR laser time before and after solder joining. LAB process. LAB process substrates

don’t need to be heated to a very high

temperature like what is needed for MR,

therefore, it only takes a few seconds to

heat up the die and perform chip joining.

In one of the early studies, two

TVs (one flip-chip fine-ball grid array

[fcFBGA] and one flip-chip ball grid

array [fcBGA]) were selected for LAB

process qualification. Fine-pitch Cu pillar

bump with bond on lead (BOL) pads were

introduced in the substrate design. One

of the great advantages of a BOL pad

is that it allows for very relaxed design

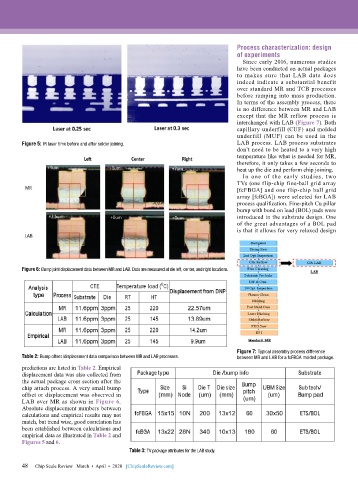

Figure 6: Bump joint displacement data between MR and LAB. Data are measured at die left, center, and right locations.

Figure 7: Typical assembly process difference

Table 2: Bump offset /displacement data comparison between MR and LAB processes. between MR and LAB for a fcFBGA molded package.

predictions are listed in Table 2. Empirical

displacement data was also collected from

the actual package cross section after the

chip attach process. A very small bump

offset or displacement was observed in

LAB over MR as shown in Figure 6.

Absolute displacement numbers between

calculations and empirical results may not

match, but trend wise, good correlation has

been established between calculations and

empirical data as illustrated in Table 2 and

Figures 5 and 6.

Table 3: TV package attributes for the LAB study.

48

48 Chip Scale Review March • April • 2020 [ChipScaleReview.com]