Page 22 - Chip Scale Review_March April_2022-digital

P. 22

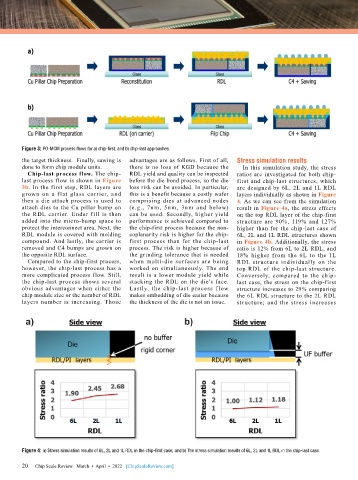

Figure 3: FO-MCM process flows for a) chip-first, and b) chip-last approaches.

the target thickness. Finally, sawing is advantages are as follows. First of all, Stress simulation results

done to form chip module units. there is no loss of KGD because the In this simulation study, the stress

Chip-last process flow. The chip- RDL yield and quality can be inspected ratios are investigated for both chip-

last process flow is shown in Figure before the die bond process, so the die first and chip-last structures, which

3b. In the first step, RDL layers are loss risk can be avoided. In particular, are designed by 6L, 2L and 1L RDL

grown on a f lat glass carrier, and this is a benefit because a costly wafer layers individually as shown in Figure

then a die attach process is used to comprising dies at advanced nodes 4. As we can see from the simulation

attach dies to the Cu pillar bump on (e.g., 7nm, 5nm, 3nm and below) result in Figure 4a, the stress effects

the RDL carrier. Under fill is then can be used. Secondly, higher yield on the top RDL layer of the chip-first

added into the micro-bump space to performance is achieved compared to structure are 90%, 119% and 127%

protect the interconnect area. Next, the the chip-first process because the non- higher than for the chip-last case of

RDL module is covered with molding coplanarity risk is higher for the chip- 6L, 2L and 1L RDL structures shown

compound. And lastly, the carrier is first process than for the chip-last in Figure 4b. Additionally, the stress

removed and C4 bumps are grown on process. The risk is higher because of ratio is 12% from 6L to 2L RDL, and

the opposite RDL surface. the grinding tolerance that is needed 18% higher from the 6L to the 1L

Compared to the chip-first process, when multi-die surfaces are being RDL structure individually on the

however, the chip-last process has a worked on simultaneously. The end top RDL of the chip-last structure.

more complicated process flow. Still, result is a lower module yield while Conversely, compared to the chip-

the chip-last process shows several stacking the RDL on the die’s face. last case, the stress on the chip-first

obvious advantages when either the Lastly, the chip-last process f low structure increases to 29% comparing

chip module size or the number of RDL makes embedding of die easier because the 6L RDL structure to the 2L RDL

layers number is increasing. Those the thickness of the die is not an issue. structure; and the stress increases

Figure 4: a) Stress simulation results of 6L, 2L and 1L RDL in the chip-first case; and b) The stress simulation results of 6L, 2L and 1L RDL in the chip-last case.

20 Chip Scale Review March • April • 2022 [ChipScaleReview.com]

20