Page 40 - Chip Scale Review_November December_2021-digital

P. 40

it has potential to fulfill diverse roles in

interconnect applications. The material

has, for example, been considered as

an oxidation barrier and as an ultrathin

diffusion barrier for metals. Researchers

have also investigated the feasibility

of using multilayer graphene wires or

nanoribbons as an alternative conductor.

Graphene, however, comes with one

major drawback: intrinsically, it does

not hold enough charge carriers to be

useful as a local interconnect. The lack

of charge carriers severely reduces its

electrical conductivity—a key metric

for interconnect performance that is

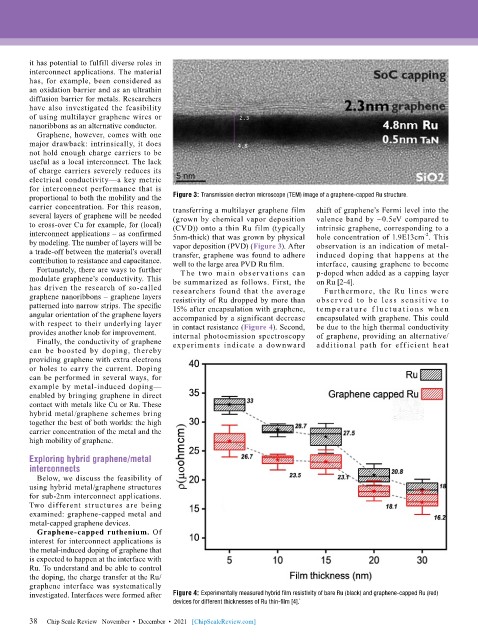

proportional to both the mobility and the Figure 3: Transmission electron microscope (TEM) image of a graphene-capped Ru structure.

carrier concentration. For this reason, transferring a multilayer graphene film shift of graphene’s Fermi level into the

several layers of graphene will be needed (grown by chemical vapor deposition valence band by ~0.5eV compared to

to cross-over Cu for example, for (local) (CVD)) onto a thin Ru film (typically intrinsic graphene, corresponding to a

interconnect applications – as confirmed 5nm-thick) that was grown by physical hole concentration of 1.9E13cm . This

-2

by modeling. The number of layers will be vapor deposition (PVD) (Figure 3). After observation is an indication of metal-

a trade-off between the material’s overall transfer, graphene was found to adhere induced doping that happens at the

contribution to resistance and capacitance. well to the large area PVD Ru film. interface, causing graphene to become

Fortunately, there are ways to further The two main observations can p-doped when added as a capping layer

modulate graphene’s conductivity. This be summarized as follows. First, the on Ru [2-4].

has driven the research of so-called researchers found that the average Furthermore, the Ru lines were

graphene nanoribbons – graphene layers resistivity of Ru dropped by more than obser ved to be less sensit ive to

patterned into narrow strips. The specific 15% after encapsulation with graphene, t e m p e r a t u r e f l u c t u a t ion s w h e n

angular orientation of the graphene layers accompanied by a significant decrease encapsulated with graphene. This could

with respect to their underlying layer in contact resistance (Figure 4). Second, be due to the high thermal conductivity

provides another knob for improvement. internal photoemission spectroscopy of graphene, providing an alternative/

Finally, the conductivity of graphene experiments indicate a downward additional path for eff icient heat

can be boosted by doping, thereby

providing graphene with extra electrons

or holes to carry the current. Doping

can be performed in several ways, for

example by metal-induced doping—

enabled by bringing graphene in direct

contact with metals like Cu or Ru. These

hybrid metal/graphene schemes bring

together the best of both worlds: the high

carrier concentration of the metal and the

high mobility of graphene.

Exploring hybrid graphene/metal

interconnects

Below, we discuss the feasibility of

using hybrid metal/graphene structures

for sub-2nm interconnect applications.

Two different structures are being

examined: graphene-capped metal and

metal-capped graphene devices.

Graphene-capped ruthenium. Of

interest for interconnect applications is

the metal-induced doping of graphene that

is expected to happen at the interface with

Ru. To understand and be able to control

the doping, the charge transfer at the Ru/

graphene interface was systematically

investigated. Interfaces were formed after Figure 4: Experimentally measured hybrid film resistivity of bare Ru (black) and graphene-capped Ru (red)

devices for different thicknesses of Ru thin-film [4].`

38 Chip Scale Review November • December • 2021 [ChipScaleReview.com]

38