Page 33 - ChipScale_Jan-Feb_2020-digital

P. 33

case of the spring elements examined produce a surface that is as flat as possible.

here, the double-acting structures A scanning electron microscopy (SEM)

proved to be advantageous on account image of a closed cavity made by LIDE is

of their structure and likely due to the shown in Figure 10. The sidewalls have a

spring force, which is approximately taper angle of approximately 1º.

twice as great in comparison with the The advantages of using a capping

other designs. wafer manufactured by LIDE for WLP

essentially result from the favorable cross-

Glass wafer-level packaging section profile. This profile fits better to

enabled by LIDE of closed cavities the rectangular silicon dies and enables

The following sections demonstrate how higher population densities as it can be

LIDE technology can manfacture closed seen in the comparison between Figure 9

pockets for glass capping wafers without and Figure 11.

having the drawback of under etching,

which is usually associated with mask

isotropic wet etching.

WLP with glass capping wafer. Wafer-

level packaging (WLP) is an established

low-cost and high-volume production Figure 14: Light microscopy image of a cross

section of a cavity made by LIDE.

technology [5]. Glass capping wafers are

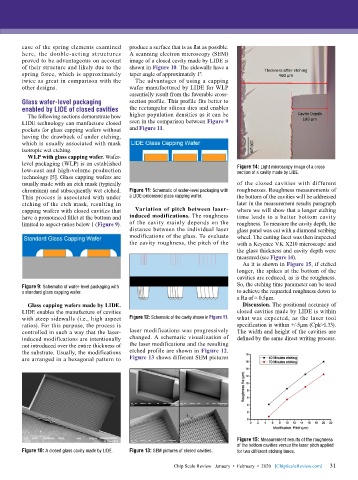

usually made with an etch mask (typically of the closed cavities with different

chromium) and subsequently wet etched. Figure 11: Schematic of wafer-level packaging with roughnesses. Roughness measurements of

This process is associated with under a LIDE-processed glass capping wafer. the bottom of the cavities will be addressed

etching of the etch mask, resulting in later in the measurement results paragraph

capping wafers with closed cavities that Variation of pitch between laser- where we will show that a longer etching

have a pronounced fillet at the bottom and induced modifications. The roughness time leads to a better bottom cavity

limited to aspect-ratios below 1 (Figure 9). of the cavity mainly depends on the roughness. To measure the cavity depth, the

distance between the individual laser glass panel was cut with a diamond scribing

modifications of the glass. To evaluate wheel. The cutting facet was then inspected

the cavity roughness, the pitch of the with a Keyence VK X210 microscope and

the glass thickness and cavity depth were

measured (see Figure 14).

As it is shown in Figure 15, if etched

longer, the spikes at the bottom of the

cavities are reduced, as is the roughness.

So, the etching time parameter can be used

Figure 9: Schematic of wafer-level packaging with

a standard glass capping wafer. to achieve the requested roughness down to

a Ra of ≈ 0.5µm.

Glass capping wafers made by LIDE. Discussion. The positional accuracy of

LIDE enables the manufacture of cavities closed cavities made by LIDE is within

with steep sidewalls (i.e., high aspect Figure 12: Schematic of the cavity shown in Figure 11. what was expected, as the laser tool

ratios). For this purpose, the process is specification is within +/-5µm (Cpk>1.33).

controlled in such a way that the laser- laser modifications was progressively The width and height of the cavities are

induced modifications are intentionally changed. A schematic visualization of defined by the same direct writing process.

not introduced over the entire thickness of the laser modifications and the resulting

the substrate. Usually, the modifications etched profile are shown in Figure 12.

are arranged in a hexagonal pattern to Figure 13 shows different SEM pictures

Figure 15: Measurement results of the roughness

of the bottom cavities versus the laser pitch applied

Figure 10: A closed glass cavity made by LIDE. Figure 13: SEM pictures of closed cavities. for two different etching times.

31

Chip Scale Review January • February • 2020 [ChipScaleReview.com] 31