Page 43 - Chip Scale Review_May June_2021-digital

P. 43

of parts to be taken from a substrate;

2) the production volume; and 3)

production leveling. In particular,

production leveling can avoid material

wastes and reduce variable costs

of production. For this production

leveling, it is necessary to possess

FOWLP technology complying with

customers’ requests and to have a

sufficient product portfolio.

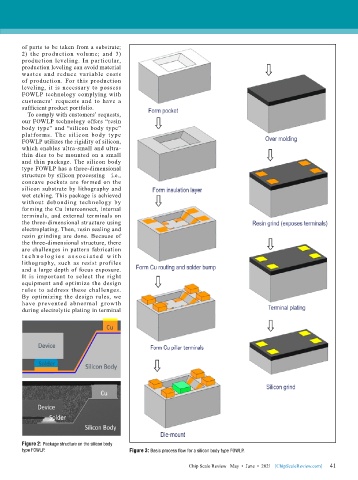

To comply with customers’ requests,

our FOWLP technology offers “resin

body type” and “silicon body type”

platfor ms. The silicon body type

FOWLP utilizes the rigidity of silicon,

which enables ultra-small and ultra-

thin dies to be mounted on a small

and thin package. The silicon body

type FOWLP has a three-dimensional

structure by silicon processing—i.e.,

concave pockets are formed on the

silicon substrate by lithography and

wet etching. This package is achieved

without debonding technology by

forming the Cu interconnect, internal

terminals, and external terminals on

the three-dimensional structure using

electroplating. Then, resin sealing and

resin grinding are done. Because of

the three-dimensional structure, there

are challenges in pattern fabrication

tec h n o l o g i e s a s s o c i a te d w i t h

lithography, such as resist profiles

and a large depth of focus exposure.

It is important to select the right

equipment and optimize the design

rules to address these challenges.

By optimizing the design rules, we

have prevented abnor mal grow th

during electrolytic plating in terminal

Figure 2: Package structure on the silicon body

type FOWLP. Figure 3: Basic process flow for a silicon body type FOWLP.

41

Chip Scale Review May • June • 2021 [ChipScaleReview.com] 41