Page 58 - ChipScale_Mar-Apr_2021-digital

P. 58

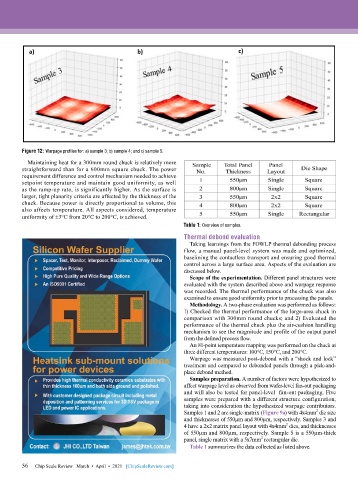

Figure 12: Warpage profiles for: a) sample 3; b) sample 4; and c) sample 5.

Maintaining heat for a 300mm round chuck is relatively more

straightforward than for a 600mm square chuck. The power

requirement difference and control mechanism needed to achieve

setpoint temperature and maintain good uniformity, as well

as the ramp-up rate, is significantly higher. As the surface is

larger, tight planarity criteria are affected by the thickness of the

chuck. Because power is directly proportional to volume, this

also affects temperature. All aspects considered, temperature

uniformity of ±3°C from 20°C to 200°C, is achieved.

Table 1: Overview of samples.

Thermal debond evaluation

Taking learnings from the FOWLP thermal debonding process

flow, a manual panel-level system was made and optimized,

baselining the contactless transport and ensuring good thermal

control across a large surface area. Aspects of the evaluation are

discussed below.

Scope of the experimentation. Different panel structures were

evaluated with the system described above and warpage response

was recorded. The thermal performance of the chuck was also

examined to ensure good uniformity prior to processing the panels.

Methodology. A two-phase evaluation was performed as follows:

1) Checked the thermal performance of the large-area chuck in

comparison with 300mm round chucks; and 2) Evaluated the

performance of the thermal chuck plus the air-cushion handling

mechanism to see the magnitude and profile of the output panel

from the defined process flow.

An 81-point temperature mapping was performed on the chuck at

three different temperatures: 100°C, 150°C, and 200°C.

Warpage was measured post-debond with a “shock and lock”

treatment and compared to debonded panels through a pick-and-

place debond method.

Samples preparation. A number of factors were hypothesized to

affect warpage level as observed from wafer-level fan-out packaging

and will also be tested for panel-level fan-out packaging. Five

samples were prepared with a different structure configuration,

taking into consideration the hypothesized warpage contributors.

Samples 1 and 2 are single-matrix (Figure 9a) with 4x4mm die size

2

and thicknesses of 550µm and 800µm, respectively. Samples 3 and

2

4 have a 2x2 matrix panel layout with 4x4mm dies, and thicknesses

of 550µm and 800µm, respectively. Sample 5 is a 550µm-thick

2

panel, single matrix with a 5x7mm rectangular die.

Table 1 summarizes the data collected as listed above.

56 Chip Scale Review March • April • 2021 [ChipScaleReview.com]

56