Page 21 - Chip Scale Review_January-February_2024-digital

P. 21

I-V characteristic of Nb/Al-AlOx/

Nb unshunted tunnel junctions (i.e.,

with respect to the Josephson critical

cur rent, sub-gap voltage, nor mal

resistance at 4.2K). A variety of

active superconducting chips with tri-

layer junctions have been assembled

to implement the ELAIC. The I–V

characteristics and switching current of

various tri-layer flip-chip JJ arrays were

measured. We measured many ELAIC

JJ arrays ranging from 40 to 20,000

JJs in series, with JJ drawn diameters

ranging between 1.0μm and 0.7μm.

I-V characteristics were measured for

ELAIC JJ arrays connected across

multiple chips through the R DL.

Figure 8d shows a representative

example of the typical I-V cur ve

obtained from these multi-chip JJ series

arrays connected through Nb and gold

lines between the chips. This confirms

connectivity between the chips through

R DL a nd t he pre se r vat ion of JJ

characteristics after RDL fabrication.

Single chip vs. the megachip

concept

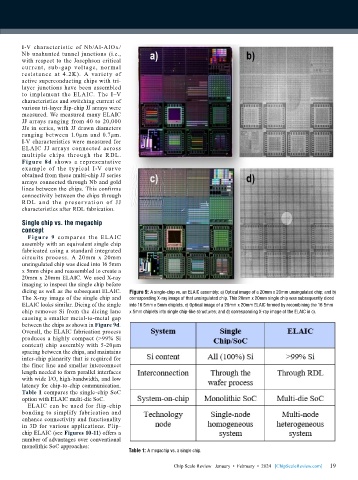

Figure 9 compares the ELA IC

assembly with an equivalent single chip

fabricated using a standard integrated

circuits process. A 20mm x 20mm

unsingulated chip was diced into 16 5mm

x 5mm chips and reassembled to create a

20mm x 20mm ELAIC. We used X-ray

imaging to inspect the single chip before

dicing as well as the subsequent ELAIC. Figure 9: A single-chip vs. an ELAIC assembly: a) Optical image of a 20mm x 20mm unsingulated chip; and b)

The X-ray image of the single chip and corresponding X-ray image of that unsingulated chip. This 20mm x 20mm single chip was subsequently diced

ELAIC looks similar. Dicing of the single into 16 5mm x 5mm chiplets. c) Optical image of a 20mm x 20mm ELAIC formed by recombining the 16 5mm

chip removes Si from the dicing lane x 5mm chiplets into single chip-like structures; and d) corresponding X-ray image of the ELAIC in c).

causing a smaller metal-to-metal gap

between the chips as shown in Figure 9d.

Overall, the ELAIC fabrication process

produces a highly compact (>99% Si

content) chip assembly with 5-20μm

spacing between the chips, and maintains

inter-chip planarity that is required for

the finer line and smaller interconnect

length needed to form parallel interfaces

with wide I/O, high-bandwidth, and low

latency for chip-to-chip communication.

Table 1 compares the single-chip SoC

option with ELAIC multi-die SoC.

ELAIC can be used for f lip-chip

bonding to simplify fabrication and

enhance connectivity and functionality

in 3D for various applications. Flip-

chip ELAIC (see Figures 10-11) offers a

number of advantages over conventional

monolithic SoC approaches:

Table 1: A megachip vs. a single chip.

19

Chip Scale Review January • February • 2024 [ChipScaleReview.com] 19