Page 21 - Chip Scale Review_November-December_2023-digital

P. 21

Automotive gate driver package with galvanically-

isolated communication linkage

By Ankur Shah, Burton Carpenter, Fred Brauchler, Di Liu, Pierre Calmes, JM Liu, Xueting Wu [NXP Semiconductors, Inc.]

W ith legislation driving to Council (AEC) Q100 Grade 1 component Meanwhile, the HV leads connect to

reduce CO 2 emissions,

electric vehicles (EVs) reliability requirements, including AEC the 400V~800V battery that powers

the drivetrain motors. For safety and

Q006 Cu wire criteria.

are a perfect alternative to internal functional reasons, the package must

combustion engine (ICE) vehicles and Galvanic isolation maintain galvanic isolation between the

government incentives are encouraging Galvanic isolation is the principle of LV and HV domains. Functional safety

faster adoption from ICE vehicles to isolating functional sections of electrical requirements for the gate drivers is at

EVs. Approximately half of all vehicles systems to prevent current flow—no Automotive Safety Integrity Level D

sold by 2030 will contain an electrified direct conduction path is permitted. (ASIL-D).

powertrain [1]. Furthermore, vehicle However, energy or information can The development and release of

electrification is driving advanced still be exchanged between the sections this gate driver package occurred in

functional safety, control and protection by other means, such as capacitive, two phases. A summary for the initial

features in automotive EV electronics. inductive (magnetic), optical, acoustic or 7.72mm creepage automotive drivetrain

Many on-board systems such as EV mechanical coupling. Furthermore, the appl icat ion wa s su m m a r i ze d by

traction inverters, DC/DC converters, device must meet certain performance Carpenter, et al. [2]. This paper provides

and on-board chargers are powered by, c r it e r i a a nd p a s s A E C G r a d e 1 an overview of the upgraded package

or connected to, high-voltage power component qualification for under-the- with greater creepage, enhanced design

sources. For example, a traction inverter hood operation. criteria, and improved HV performance:

converts DC voltage from a high-voltage An advanced gate driver package achieving a comparative tracking

battery into a high-current, multi-phase ma kes di rect physical elect r ical index (CTI) >600V (Material Group 1),

AC voltage to drive the traction motor. con nect ions to bot h H V a nd LV creepage >8mm, and common mode

Microcontroller unit (MCU) output is domains, therefore, safety and functional transient immunity (CMTI) >200V/nsec.

not capable of driving a power device requirements necessitate that design,

(insulated-gate bipolar transistor [IGBT] testing and manufacture of the gate driver Product features

or silicon carbide [SiC]), which in turn component ensure galvanic isolation NXP’s gate driver IC (GDIC) is

drives the traction motor. Therefore, to between these domains. functionally safe (ASIL C/D compliant)

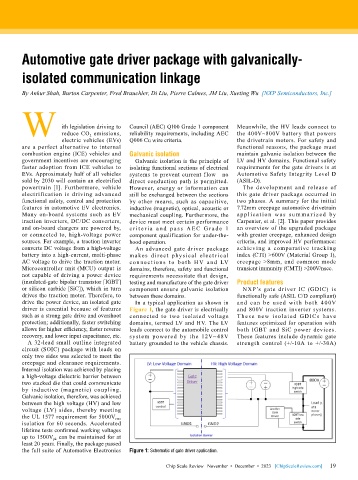

drive the power device, an isolated gate In a typical application as shown in and can be used with both 400V

driver is essential because of features Figure 1, the gate driver is electrically and 800V traction inverter systems.

such as a strong gate drive and overshoot connected to two isolated voltage T hese new isolated GDICs have

protection; additionally, faster switching domains, termed LV and HV. The LV features optimized for operation with

allows for higher efficiency, faster reverse leads connect to the automobile control both IGBT and SiC power devices.

recovery, and lower input capacitance, etc. system powered by the 12V~ 48V These features include dynamic gate

A 32-lead small outline integrated battery grounded to the vehicle chassis. strength control (+/-10A to +/-30A)

circuit (SOIC) package with leads on

only two sides was selected to meet the

creepage and clearance requirements.

Internal isolation was achieved by placing

a high-voltage dielectric barrier between

two stacked die that could communicate

by inductive (magnetic) coupling.

Galvanic isolation, therefore, was achieved

between the high voltage (HV) and low

voltage (LV) sides, thereby meeting

the UL 1577 requirement for 5000V rms

isolation for 60 seconds. Accelerated

lifetime tests confirmed working voltages

up to 1500V pk can be maintained for at

least 20 years. Finally, the package passed

the full suite of Automotive Electronics Figure 1: Schematic of gate driver application.

19

Chip Scale Review November • December • 2023 [ChipScaleReview.com] 19