Page 25 - Chip Scale Review_May June_2023-digital

P. 25

Illumination inspection technology for defect detection

on advanced IC substrates

By Cheolkyu Kim, Burhan Ali, JungHyun Kim [Onto Innovation]

Jong Eun Park, Misun Hwang, Chan Jin Park, [Samsung Electro-Mechanics (SEMCO)]

A cross the semiconductor potentially magnified as each new layer material of epoxy polymer matrixes

industry, advanced integrated

up. In some cases, the number of layers

electrical properties of epoxy polymer can

circuit (IC) substrate (AICS) of ABF on the FC-BGA substrate is built and inorganic fillers. The chemical and

supplies are low. The causes vary, from a of build-up may reach 20. With each be easily tailored by changing chemical

limited number of suppliers who can meet additional layer, the potential for killer components to meet various material

performance requirements, to constrained defects increases, whether the cause is requirements [1]. Another advantage of

production capacities, and increased ABF residue in laser-drilled vias, poor ABF is that it facilitates the formation of

demand resulting from the adoption of dry-film resist development, or the under- fine-pitch lines/spaces because its surface

high-performance mobile devices, as well and over-etching of Cu seed. is receptive to laser processing and direct

as advanced technologies like artificial For advanced packaging houses, copper plating. This advantage, in part,

intelligence (AI) and high-performance addressing this issue is a matter of makes ABF an ideal material for devices

computing (HPC). And without question, considerable interest. After all, few where miniaturization is a driving force

the ongoing shortage of Ajinomoto build- businesses are not interested in reducing for innovation. For pattern formation on

up film (ABF), a necessary component waste and cost, while more efficiently the build-up layers of IC substrate, dry

of many AICS, plays a significant role as utilizing an in-demand resource in short- film is commonly used together with a

well. One area where this shortage of ABF supply, like ABF. Fortunately, optical semi-additive process to achieve copper

and AICS is having a significant impact inspection technologies are available lines down to 5µm/5µm or smaller lines/

is in the manufacturing of flip-chip ball- that can discover these difficult-to-detect spaces in laminated substrates.

grid array (FC-BGA) packages—the most defects. In this article we will discuss a Because the main function of an

advanced substrates to meet the electrical proven macro inspection technology that IC substrate is to create an electrical

and thermal requirements for IC chips with is uniquely capable of finding defects and connection between the IC and circuit

high numbers of I/Os. errors in AICS. board, the most serious process issues

To address the substrate shortage, are shorts or open circuits, both of which

suppliers of FC-BGA substrates are Inspection challenges require inspection tools to find defects. For

ramping up capacity. However, that Before we move for ward, let’s example, poor dry-film development leads

acceleration comes with high costs due to reexamine why ABF has become an to bad patterning, which, in turn, leads to

the fact that the AICS process is burdened important component in manufacturing poor or bad signal integrity. Meanwhile,

by low yields resulting from the presence AICS. In an AICS, specifically those during the curing process, particles or

of defects that are left undetected by many made for FC-BGA, Cu is used for bubbles under laminated ABF can cause

macro inspection systems. Furthermore, electrical connections and ABF is used for pattern distortions. Left after the formation

that inability to detect certain defects is insulation (Figure 1). ABF is a compound of vias through the ABF by laser ablation,

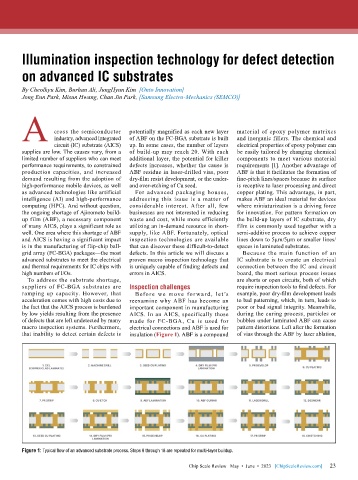

Figure 1: Typical flow of an advanced substrate process. Steps 9 through 18 are repeated for multi-layer buildup.

23

Chip Scale Review May • June • 2023 [ChipScaleReview.com] 23