Page 20 - Chip Scale Review_May June_2023-digital

P. 20

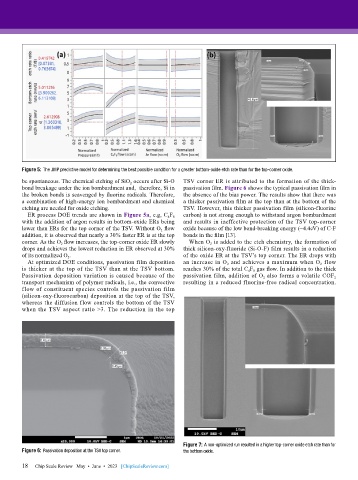

Figure 5: The JMP predictive model for determining the best possible condition for a greater bottom-oxide etch rate than for the top-corner oxide.

be spontaneous. The chemical etching of SiO 2 occurs after Si-O TSV corner ER is attributed to the formation of the thick-

bond breakage under the ion bombardment and, therefore, Si in passivation film. Figure 6 shows the typical passivation film in

the broken bonds is scavenged by fluorine radicals. Therefore, the absence of the bias power. The results show that there was

a combination of high-energy ion bombardment and chemical a thicker passivation film at the top than at the bottom of the

etching are needed for oxide etching. TSV. However, this thicker passivation film (silicon-fluorine

ER process DOE trends are shown in Figure 5a, e.g, C 4 F 8 carbon) is not strong enough to withstand argon bombardment

with the addition of argon results in bottom-oxide ERs being and results in ineffective protection of the TSV top-corner

lower than ERs for the top corner of the TSV. Without O 2 flow oxide because of the low bond-breaking energy (~4.4eV) of C-F

addition, it is observed that nearly a 30% faster ER is at the top bonds in the film [13].

corner. As the O 2 flow increases, the top-corner oxide ER slowly When O 2 is added to the etch chemistry, the formation of

drops and achieves the lowest reduction in ER observed at 30% thick silicon-oxy-fluoride (Si-O-F) film results in a reduction

of its normalized O 2 . of the oxide ER at the TSV’s top corner. The ER drops with

At optimized DOE conditions, passivation film deposition an increase in O 2 and achieves a maximum when O 2 flow

is thicker at the top of the TSV than at the TSV bottom. reaches 30% of the total C 4 F 8 gas flow. In addition to the thick

Passivation deposition variation is caused because of the passivation film, addition of O 2 also forms a volatile COF 2

transport mechanism of polymer radicals, i.e., the convective resulting in a reduced fluorine-free radical concentration.

flow of constituent species controls the passivation film

(silicon-oxy-fluorocarbon) deposition at the top of the TSV,

whereas the diffusion flow controls the bottom of the TSV

when the TSV aspect ratio >3. The reduction in the top

Figure 7: A non-optimized run resulted in a higher top-corner oxide etch rate than for

Figure 6: Passivation deposition at the TSV top corner. the bottom oxide.

18 Chip Scale Review May • June • 2023 [ChipScaleReview.com]

18