Page 17 - Chip Scale Review_May June_2023-digital

P. 17

TSV oxide etch-back optimization for the via-last

integration scheme

By Bhesetti S. S. Chandra Rao, Hemanth K. Cheemalamarri, Darshini Senthilkumar

[Institute of Microelectronics, Agency for Science, Technology and Research (A*STAR)]

T hrough-silicon via (TSV) scaling to enable higher integration

technology has become the key

heterogeneous technologies [3,4].

driver for advanced electronic densities along with the integration of

packages such as those used in 3D stacking The use of TSVs has become a

and backside illuminated image (BSI) prominent interconnect technology for

sensor applications. Among the various signal integrity through vertical stacking

possible methods of integrating TSVs such [5-6]. There are several approaches for

as via first, via middle and via last, the via- TSV formation. The via-first approach

last method has gained much attention. The creates the TSVs before the front-end-of-

via-last method helps reduce the impact line (FEOL) and BEOL processes. The

on back-end-of-line (BEOL) processing via-middle approach carries out FEOL

and does not require a TSV-reveal process fabrication, followed by TSV and BEOL

flow. However, the via-last process scheme fabrications. The via-last approach [6]

requires a more reliable TSV bottom-oxide forms the TSVs after FEOL and BEOL

etch-back process for making contact with fabrications. In the via-after bonding

the underneath interconnect layer. One approach, vias are formed after bonding

potential challenge with respect to the either chip-to-wafer (C2W) schemes

oxide etch-back process is in protecting the or wafer-to-wafer (W2W) schemes.

top corner of the TSV liner oxide to ensure Depending on the integration scheme, the

better electrical reliability. This challenge via-last or via-after bonding is selected

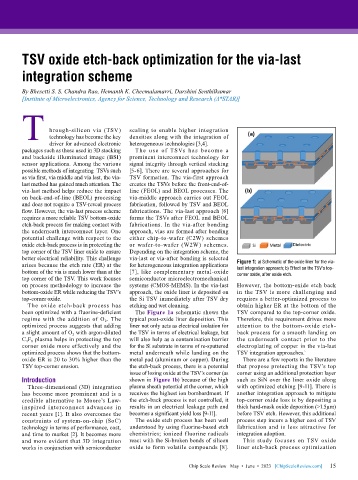

arises because the etch rate (ER) at the for heterogeneous integration applications Figure 1: a) Schematic of the oxide liner for the via-

bottom of the via is much lower than at the [7], like complementary metal-oxide last integration approach; b) Effect on the TSV’s top-

top corner of the TSV. This work focuses semiconductor microelectromechanical corner oxide, after oxide etch.

on process methodology to increase the systems (CMOS-MEMS). In the via-last However, the bottom-oxide etch back

bottom-oxide ER while reducing the TSV’s approach, the oxide liner is deposited on in the TSV is more challenging and

top-corner oxide. the Si TSV immediately after TSV dry requires a better-optimized process to

The oxide etch-back process has etching and wet cleaning. obtain higher ER at the bottom of the

been optimized with a fluorine-deficient The Figure 1a schematic shows the TSV compared to the top-corner oxide.

regime with the addition of O 2 . The typical post-oxide liner deposition. This Therefore, this requirement drives more

optimized process suggests that adding liner not only acts as electrical isolation for attention to the bottom-oxide etch-

a slight amount of O 2 with argon-diluted the TSV in terms of electrical leakage, but back process for a smooth landing on

C 4 F 8 plasma helps in protecting the top will also help as a contamination barrier the underneath contact prior to the

corner oxide more effectively and the for the Si substrate in terms of re-sputtered electroplating of copper in the via-last

optimized process shows that the bottom- metal underneath while landing on the TSV integration approaches.`

oxide ER is 20 to 30% higher than the metal pad (aluminum or copper). During There are a few reports in the literature

TSV top-corner erosion. the etch-back process, there is a potential that propose protecting the TSV’s top

issue of losing oxide at the TSV’s corner (as corner using an additional protection layer

Introduction shown in Figure 1b) because of the high such as SiN over the liner oxide along

Three-dimensional (3D) integration plasma sheath potential at the corner, which with optimized etching [9-11]. There is

has become more prominent and is a receives the highest ion bombardment. If another integration approach to mitigate

credible alternative to Moore’s Law- the etch-back process is not controlled, it top-corner oxide loss is by depositing a

inspired interconnect advances in results in an electrical leakage path and thick hard-mask oxide deposition (>1.5µm)

recent years [1]. It also overcomes the becomes a significant yield loss [9-11]. before TSV etch. However, this additional

constraints of system-on-chip (SoC) The oxide etch process has been well process step incurs a higher cost of TSV

technology in terms of performance, cost, understood by using fluorine-based etch fabrication and is less attractive for

and time to market [2]. It becomes more chemistries; ionized fluorine radicals integration adoption.

and more evident that 3D integration react with the Si-broken bonds of silicon This study focuses on TSV oxide

works in conjunction with semiconductor oxide to form volatile compounds [8]. liner etch-back process optimization

15

Chip Scale Review May • June • 2023 [ChipScaleReview.com] 15