Page 25 - ChipScale_Mar-Apr_2020-digital

P. 25

Holistic approach to improve the reliability of

sub-5µm L/S Cu RDLs

By Ralf Schmidt, Jan Knaup, Ulrich Memmert, Jens Palm, Cornelia Jäger, Stefan Pieper, Uwe Kirbach, Thomas Beck [Atotech Group]

A d va n c e d p a c k a g i ng

t e c h n o l og ie s e n a b l e

f a s t er , t h i n n er , a n d

m o r e ef f ic ie n t m o bi le d e v ic e s .

In particular, fan-out wafer-level

packaging (FOWLP) allows for higher

performance, decreasing form factor,

and significant cost reduction [1].

Redistribution layers (RDLs) serve as

rerouting of the connections within

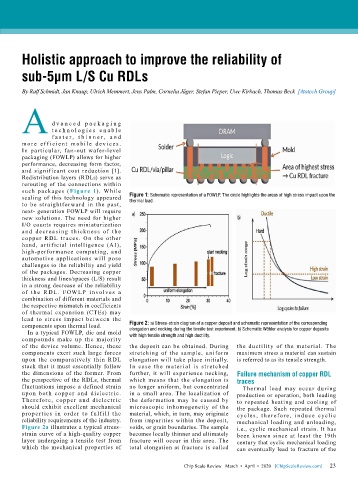

such packages (Figure 1). While

scaling of this technology appeared Figure 1: Schematic representation of a FOWLP. The circle highlights the areas of high stress impact upon the

to be straightforward in the past, thermal load.

next- generation FOWLP will require

new solutions. The need for higher

I/O counts requires miniaturization

a nd decreasi ng t h ick ness of t he

copper R DL traces. On the other

hand, artificial intelligence (AI),

high-performance computing, and

automotive applications will pose

challenges to the reliability and yield

of the packages. Decreasing copper

thickness and lines/spaces (L/S) result

in a strong decrease of the reliability

of t he R DL . FOW LP i nvolve s a

combination of different materials and

the respective mismatch in coefficients

of thermal expansion (CTEs) may

lead to stress impact between the

components upon thermal load. Figure 2: a) Stress-strain diagram of a copper deposit and schematic representation of the corresponding

In a typical FOWLP, die and mold elongation and necking during the tensile test experiment. b) Schematic Wöhler analysis for copper deposits

with high tensile strength and high ductility.

compounds make up the majority

of the device volume. Hence, these the deposit can be obtained. During the ductility of the material. The

components exert such large forces stretching of the sample, uniform maximum stress a material can sustain

upon the comparatively thin RDL elongation will take place initially. is referred to as its tensile strength.

stack that it must essentially follow In case the material is st retched

the dimensions of the former. From further, it will experience necking, Failure mechanism of copper RDL

the perspective of the RDLs, thermal which means that the elongation is traces

fluctuations impose a defined strain no longer uniform, but concentrated Thermal load may occur during

upon both copper and dielectric. in a small area. The localization of production or operation, both leading

Therefore, copper and dielect r ic the deformation may be caused by to repeated heating and cooling of

should exhibit excellent mechanical microscopic inhomogeneity of the the package. Such repeated thermal

proper ties in order to f ulf ill the material, which, in turn, may originate cycle s, t he refore, i nduce cycl ic

reliability requirements of the industry. from impurities within the deposit, mechanical loading and unloading,

Figure 2a illustrates a typical stress- voids, or grain boundaries. The sample i.e., cyclic mechanical strain. It has

strain curve of a high-quality copper becomes locally thinner and ultimately been known since at least the 19th

layer undergoing a tensile test from fracture will occur in this area. The century that cyclic mechanical loading

which the mechanical properties of total elongation at fracture is called can eventually lead to fracture of the

23

Chip Scale Review March • April • 2020 [ChipScaleReview.com] 23