Page 49 - Chip Scale Review Sep Oct_2022-digital

P. 49

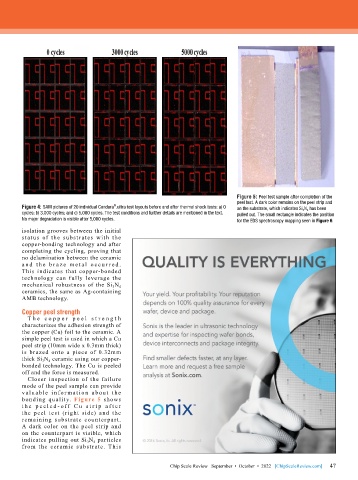

Figure 5: Peel test sample after completion of the

peel test. A dark color remains on the peel strip and

®

Figure 4: SAM pictures of 20 individual Condura .ultra test layouts before and after thermal shock tests: a) 0 on the substrate, which indicates Si 3 N 4 has been

cycles; b) 3,000 cycles; and c) 5,000 cycles. The test conditions and further details are mentioned in the text. pulled out. The small rectangle indicates the position

No major degradation is visible after 5,000 cycles. for the EDS spectroscopy mapping seen in Figure 6.

isolation grooves between the initial

stat us of the subst rates with the

copper-bonding technology and after

completing the cycling, proving that

no delamination between the ceramic

a n d t h e b r a z e m e t a l o c c u r r e d .

This indicates that copper-bonded

technology can fully leverage the

mechanical robustness of the Si 3 N 4

ceramics, the same as Ag-containing

AMB technology.

Copper peel strength

T h e c o p p e r p e e l s t r e ng t h

characterizes the adhesion strength of

the copper (Cu) foil to the ceramic. A

simple peel test is used in which a Cu

peel strip (10mm wide x 0.3mm thick)

is brazed onto a piece of 0.32mm

thick Si 3 N 4 ceramic using our copper-

bonded technology. The Cu is peeled

off and the force is measured.

Closer inspection of the failure

mode of the peel sample can provide

va lu a ble i n fo r m a t io n a b out t he

bonding quality. Figure 5 shows

t h e p e e l e d - o f f C u s t r i p a f t e r

the peel test (right side) and the

remaining substrate counter par t.

A dark color on the peel strip and

on the counterpart is visible, which

indicates pulling out Si 3 N 4 particles

from the ceramic substrate. This

47

Chip Scale Review September • October • 2022 [ChipScaleReview.com] 47