Page 45 - Chip Scale Review Sep Oct_2022-digital

P. 45

between -60°C and 100°C (Range 1) and

0.02°C between 101°C and 230°C (Range

2). The device’s uncertainty is, therefore,

maximally 0.02°C. A measurement wafer,

often consisting of up to 17 sensors, has

a significantly higher uncertainty of

approximately 0.05°C due to the sensor-

to-sensor accuracy deviation. It is also

necessary to factor in the absolute accuracy

of 0.03°C (taken from the wafer specification

sheet), which leaves you with a total device

uncertainty of 0.058°C—almost three times

more than the maximum uncertainty of the

single sensor. To calculate the calibration

reliability, the tool’s uncertainty is added to

the method (repeatability tests) uncertainty.

Figure 4: Over the course of three days, the temperature increased and decreased corresponding to the As a result, the calibration reliability

of the ERS system is 0.022°C, which is

temperature changes in the outside environment.

considerably lower than the reliability of the

increase of 0.2°C on the test surface was case, using an ERS ultra-low noise (ULN) measurement wafer (i.e., 0.065°C).

seen over five hours (Figure 3a)—this chuck led to a larger deviation than using

is called a temperature drift. However, a low-noise or high-thermal uniformity

looking again at a 30-minute interval (HTU) chuck. This is caused by the

in Figure 3b, the observed reliability additional ceramic plate in the ULN chuck,

was 10mK. which creates a larger separation between

To investigate the cause of the the top plate and the thermal plate.

temperature drift, an additional test

was done at 200°C, but this time a Measurement wafer vs. single-

measurement wafer was used. Again, the sensor probing tool

same gradual heating effect was observed. After obtaining and validating the test

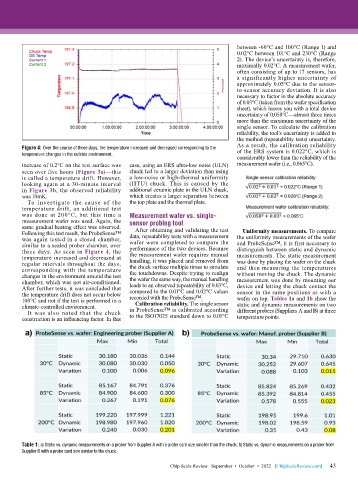

Following this test result, the ProbeSense™ data, repeatability tests with a measurement Uniformity measurements. To compare

was again tested in a closed chamber, wafer were completed to compare the the uniformity measurements of the wafer

similar to a sealed prober chamber, over performance of the two devices. Because and ProbeSense™, it is first necessary to

three days. As seen in Figure 4, the the measurement wafer requires manual distinguish between static and dynamic

temperature increased and decreased at handling, it was placed and removed from measurements. The static measurement

regular intervals throughout the days, the chuck surface multiple times to simulate was done by placing the wafer on the chuck

corresponding with the temperature the touchdowns. Despite trying to realign and then measuring the temperatures

changes in the environment around the test the wafer the same way, the manual handling without moving the chuck. The dynamic

chamber, which was not air-conditioned. leads to an observed repeatability of 0.03°C, measurement was done by mounting our

After further tests, it was concluded that compared to the 0.01°C and 0.02°C values device and letting the chuck contact the

the temperature drift does not occur below recorded with the ProbeSense™. sensor in the same positions as with a

100°C and not if the test is performed in a Calibration reliability. The single sensor wafer on top. Tables 1a and 1b show the

climate-controlled environment. in ProbeSense™ is calibrated according static and dynamic measurements on two

It was also noted that the chuck different probers (Suppliers A and B) at three

construction is an influencing factor. In this to the ISO17025 standard down to 0.01°C temperature points.

Table 1: a) Static vs. dynamic measurements on a prober from Supplier A with a probe card size smaller than the chuck; b) Static vs. dynamic measurements on a prober from

Supplier B with a probe card size similar to the chuck.

43

Chip Scale Review September • October • 2022 [ChipScaleReview.com] 43