Page 40 - Chip Scale Review Sep Oct_2022-digital

P. 40

Addressing temperature accuracy and uniformity

measurements in wafer probing

By Klemens Reitinger, Bengt Haunerland, Sophia Oldeide [ERS electronic GmbH]

T emperature has always been thin wafer with multiple embedded sensors. New calibration concept

an important parameter when

To tackle the issues noted above and

are notable advantages of this type of tool.

testing sensor devices, but the Fast test times and instant uniformity data lower the measurement uncertainty, there is

trend is moving from simple, functional Because of its multi-sensor design concept, a need to eliminate the inherent weaknesses

tests, to calibration at certain temperatures. however, there will always be a sensor-to- of the tools’ designs. ERS’s ProbeSense™

Consequently, these devices, like sensor accuracy deviation. Its operation is also is a wafer prober-dedicated tool that offers

temperature, gas, humidity, and pressure associated with a great deal of effort because a new concept for temperature calibration

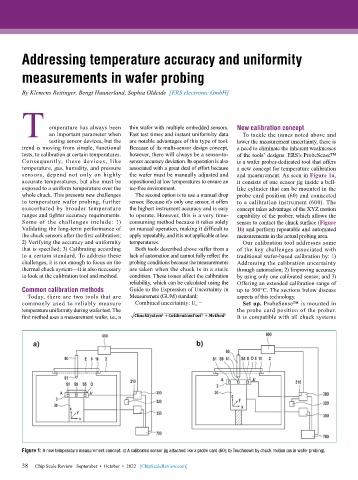

sensors, depend not only on highly the wafer must be manually adjusted and and measurement. As seen in Figure 1a,

accurate temperatures, but also must be repositioned at low temperatures to ensure an it consists of one sensor jig inside a bell-

exposed to a uniform temperature over the ice-free environment. like cylinder that can be mounted in the

whole chuck. This presents new challenges The second option is to use a manual drop probe card position (60) and connected

to temperature wafer probing, further sensor. Because it’s only one sensor, it offers to a calibration instrument (600). The

exacerbated by broader temperature the highest instrument accuracy and is easy concept takes advantage of the XYZ motion

ranges and tighter accuracy requirements. to operate. However, this is a very time- capability of the prober, which allows the

Some of the challenges include: 1) consuming method because it relies solely sensor to contact the chuck surface (Figure

Validating the long-term performance of on manual operation, making it difficult to 1b) and perform repeatable and automated

the chuck sensors after the first calibration; apply repeatably, and it is not applicable at low measurements in the actual probing area.

2) Verifying the accuracy and uniformity temperatures. Our calibration tool addresses some

that is specified; 3) Calibrating according Both tools described above suffer from a of the key challenges associated with

to a certain standard. To address these lack of automation and cannot fully reflect the traditional wafer-based calibration by: 1)

challenges, it is not enough to focus on the probing conditions because the measurements Addressing the calibration uncertainty

thermal chuck system—it is also necessary are taken when the chuck is in a static through automation; 2) Improving accuracy

to look at the calibration tool and method. condition. These issues affect the calibration by using only one calibrated sensor; and 3)

reliability, which can be calculated using the Offering an extended calibration range of

Common calibration methods Guide to the Expression of Uncertainty in up to 300°C. The sections below discuss

Today, there are two tools that are Measurement (GUM) standard: aspects of this technology.

commonly used to reliably measure Combined uncertainty: U c = Set up. ProbeSense™ is mounted in

temperature uniformity during wafer test. The the probe card position of the prober.

first method uses a measurement wafer, i.e., a It is compatible with all chuck systems

Figure 1: A new temperature measurement concept: a) A calibrated sensor jig attached like a probe card (60); b) Touchdown by chuck motion (as in wafer probing).

38 Chip Scale Review September • October • 2022 [ChipScaleReview.com]

38