Page 37 - Chip Scale Review Sep Oct_2022-digital

P. 37

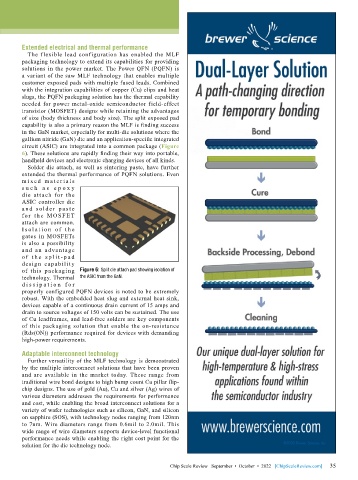

Extended electrical and thermal performance

The f lexible lead configuration has enabled the MLF

packaging technology to extend its capabilities for providing

solutions in the power market. The Power QFN (PQFN) is

a variant of the saw MLF technology that enables multiple

customer exposed pads with multiple fused leads. Combined

with the integration capabilities of copper (Cu) clips and heat

slugs, the PQFN packaging solution has the thermal capability

needed for power metal-oxide semiconductor field-effect

transistor (MOSFET) designs while retaining the advantages

of size (body thickness and body size). The split exposed pad

capability is also a primary reason the MLF is finding success

in the GaN market, especially for multi-die solutions where the

gallium nitride (GaN) die and an application-specific integrated

circuit (ASIC) are integrated into a common package (Figure

6). These solutions are rapidly finding their way into portable,

handheld devices and electronic charging devices of all kinds.

Solder die attach, as well as sintering paste, have further

extended the thermal performance of PQFN solutions. Even

m i x e d m a t e r i a l s

s u c h a s e p o x y

die attach for the

ASIC controller die

a nd s ol d e r p a s t e

fo r t h e MO SF E T

attach are common.

I s o l a t i o n o f t h e

gates in MOSFETs

is also a possibility

and an advantage

o f t h e s p l i t- p a d

desig n capabilit y

of this packaging Figure 6: Split die attach pad showing isolation of

technology. Thermal the ASIC from the GaN.

d i s s i p a t i on f o r

properly configured PQFN devices is noted to be extremely

robust. With the embedded heat slug and external heat sink,

devices capable of a continuous drain current of 15 amps and

drain to source voltages of 150 volts can be sustained. The use

of Cu leadframes, and lead-free solders are key components

of this packaging solution that enable the on-resistance

(Rds(ON)) performance required for devices with demanding

high-power requirements.

Adaptable interconnect technology

Further versatility of the MLF technology is demonstrated

by the multiple interconnect solutions that have been proven

and are available in the market today. These range from

traditional wire bond designs to high bump count Cu pillar flip-

chip designs. The use of gold (Au), Cu and silver (Ag) wires of

various diameters addresses the requirements for performance

and cost, while enabling the broad interconnect solutions for a

variety of wafer technologies such as silicon, GaN, and silicon

on sapphire (SOS), with technology nodes ranging from 120nm

to 7nm. Wire diameters range from 0.6mil to 2.0mil. This

wide range of wire diameters supports device-level functional

performance needs while enabling the right cost point for the

solution for the die technology node.

35

Chip Scale Review September • October • 2022 [ChipScaleReview.com] 35