Page 42 - Chip Scale Review Sep Oct_2022-digital

P. 42

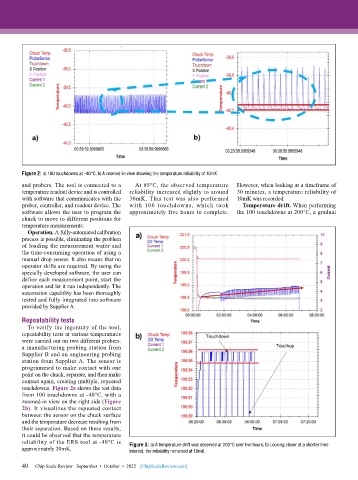

Figure 2: a) 100 touchdowns at -40°C; b) A zoomed-in view showing the temperature reliability of 10mK.

and probers. The tool is connected to a At 85°C, the observed temperature However, when looking at a timeframe of

temperature readout device and is controlled reliability increased slightly to around 30 minutes, a temperature reliability of

with software that communicates with the 30mK. This test was also performed 10mK was recorded.

prober, controller, and readout device. The with 100 touchdowns, which took Temperature drift. When performing

software allows the user to program the approximately five hours to complete. the 100 touchdowns at 200°C, a gradual

chuck to move to different positions for

temperature measurements.

Operation. A fully-automated calibration

process is possible, eliminating the problem

of loading the measurement wafer and

the time-consuming operation of using a

manual drop sensor. It also means that no

operator skills are required. By using the

specially developed software, the user can

define each measurement point, start the

operation and let it run independently. The

automation capability has been thoroughly

tested and fully integrated into software

provided by Supplier A.

Repeatability tests

To verify the ingenuity of the tool,

repeatability tests at various temperatures

were carried out on two different probers:

a manufacturing probing station from

Supplier B and an engineering probing

station from Supplier A. The sensor is

programmed to make contact with one

point on the chuck, separate, and then make

contact again, creating multiple, repeated

touchdowns. Figure 2a shows the test data

from 100 touchdowns at -40°C, with a

zoomed-in view on the right side (Figure

2b). It visualizes the repeated contact

between the sensor on the chuck surface

and the temperature decrease resulting from

their separation. Based on these results,

it could be observed that the temperature

reliability of the ERS tool at -40°C is Figure 3: a) A temperature drift was observed at 200°C over five hours; b) Looking closer at a shorter time

approximately 20mK. interval, the reliability remained at 10mK.

40 Chip Scale Review September • October • 2022 [ChipScaleReview.com]

40