Page 46 - Chip Scale Review_November December_2021-digital

P. 46

The system’s 2.2x magnification

projection lens enables up to a 250mm

x 250mm exposure field size, with

3µm line/space resolution, ±400ppm

mag nif ication compensation and

±100ppm anamorphic magnification

compensation, with overlay accuracy

better than 1µm.

Low lens distortion and accurate

step and settle movement are also key

to meeting the overlay and uniformity

requi rements. Distor t ion i n this

system is less than 1μm across the

250mm exposure field. The system’s

stage is driven by 8 motors to ensure

accurate step and settle behavior, even

when loaded with the weight of the

large panel.

Figure 3: a) (left) The exposure layout for a 515mm x 510mm panel using a large exposure field (250mm x During the FOPLP substrate build

250mm) compared with b) (right) the exposure layout of a smaller field (59mm x 59mm). process, many layers of RDL and ABF

are added to the panel. These films

and a smaller field (59mm x 59mm) and Equation 2. With feature sizes in distort the panel in the X axis, Y axis

on a 510mm x 515mm panel. With the the micrometer range, the resolution and Z axis during thermal cycling.

large exposure field, the panel can be requirements for advanced packaging Magnification compensation allows

completely exposed with just four shots, and advanced IC substrates are less the system to accommodate these

while the smaller field requires 64 shots. demanding than requirements for front- changes in the substrate. Two kinds

end lithography, where feature sizes of compensation are needed. Isotropic

Lithography system are 1,000 times smaller. At the same magnification shrinks or enlarges

The increased topological variation time, the use of thicker resist films and the pattern equally in all directions.

expected for larger panels, physical larger variations in substrate topography Anamorphic magnification enlarges or

distortion during the RDL build-up require greater DOF. The projection shrinks the patterns anisotropically to

process and the greater feature heights optics of the lithography system used in correct for distorted panel registration

typical of RDL all contribute to the this demonstration were designed with errors. Both adjustments are necessary

requirement for more depth of focus a lower numerical aperture to meet both to achieve good overlay and maintain

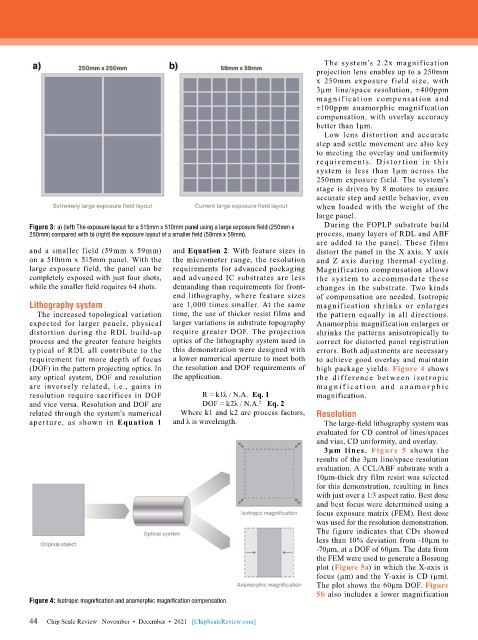

(DOF) in the pattern projecting optics. In the resolution and DOF requirements of high package yields. Figure 4 shows

any optical system, DOF and resolution the application. the difference bet ween isot ropic

are inversely related, i.e., gains in m a g n i f i c a t i o n a n d a n a m o r ph i c

resolution require sacrifices in DOF R = k1λ / N.A. Eq. 1 magnification.

and vice versa. Resolution and DOF are DOF = k2λ / N.A.² Eq. 2

related through the system’s numerical Where k1 and k2 are process factors, Resolution

aperture, as shown in Equation 1 and λ is wavelength. The large-field lithography system was

evaluated for CD control of lines/spaces

and vias, CD uniformity, and overlay.

3µm lines. Figure 5 shows the

results of the 3µm line/space resolution

evaluation. A CCL/ABF substrate with a

10µm-thick dry film resist was selected

for this demonstration, resulting in lines

with just over a 1:3 aspect ratio. Best dose

and best focus were determined using a

focus exposure matrix (FEM). Best dose

was used for the resolution demonstration.

The figure indicates that CDs showed

less than 10% deviation from -10μm to

-70μm, at a DOF of 60μm. The data from

the FEM were used to generate a Bossung

plot (Figure 5a) in which the X-axis is

focus (μm) and the Y-axis is CD (μm).

The plot shows the 60μm DOF. Figure

5b also includes a lower magnification

Figure 4: Isotropic magnification and anamorphic magnification compensation.

44

44 Chip Scale Review November • December • 2021 [ChipScaleReview.com]