Page 47 - Chip Scale Review_November December_2021-digital

P. 47

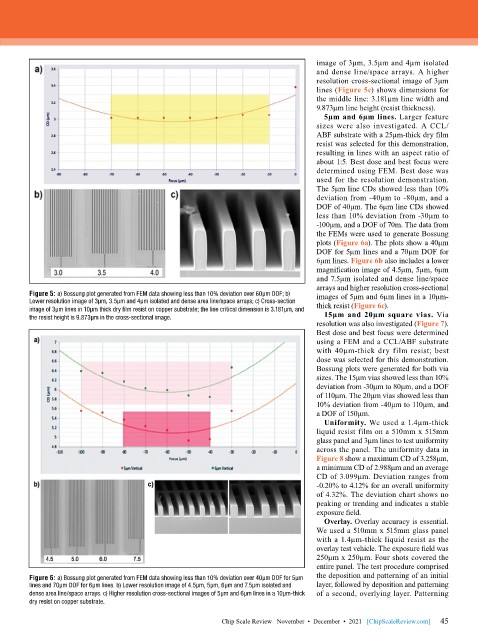

image of 3μm, 3.5μm and 4μm isolated

and dense line/space arrays. A higher

resolution cross-sectional image of 3μm

lines (Figure 5c) shows dimensions for

the middle line: 3.181µm line width and

9.873µm line height (resist thickness).

5µm and 6µm lines. Larger feature

sizes were also investigated. A CCL/

ABF substrate with a 25µm-thick dry film

resist was selected for this demonstration,

resulting in lines with an aspect ratio of

about 1:5. Best dose and best focus were

determined using FEM. Best dose was

used for the resolution demonstration.

The 5μm line CDs showed less than 10%

deviation from -40μm to -80μm, and a

DOF of 40μm. The 6μm line CDs showed

less than 10% deviation from -30μm to

-100μm, and a DOF of 70m. The data from

the FEMs were used to generate Bossung

plots (Figure 6a). The plots show a 40μm

DOF for 5μm lines and a 70μm DOF for

6μm lines. Figure 6b also includes a lower

magnification image of 4.5μm, 5μm, 6μm

and 7.5μm isolated and dense line/space

arrays and higher resolution cross-sectional

Figure 5: a) Bossung plot generated from FEM data showing less than 10% deviation over 60μm DOF; b) images of 5μm and 6μm lines in a 10μm-

Lower resolution image of 3μm, 3.5μm and 4μm isolated and dense area line/space arrays; c) Cross-section thick resist (Figure 6c).

image of 3µm lines in 10µm thick dry film resist on copper substrate; the line critical dimension is 3.181µm, and

the resist height is 9.873µm in the cross-sectional image. 15µm and 20µm square vias. Via

resolution was also investigated (Figure 7).

Best dose and best focus were determined

using a FEM and a CCL/ABF substrate

with 40µm-thick dry film resist; best

dose was selected for this demonstration.

Bossung plots were generated for both via

sizes. The 15μm vias showed less than 10%

deviation from -30μm to 80μm, and a DOF

of 110μm. The 20μm vias showed less than

10% deviation from -40μm to 110μm, and

a DOF of 150μm.

Uniformity. We used a 1.4µm-thick

liquid resist film on a 510mm x 515mm

glass panel and 3µm lines to test uniformity

across the panel. The uniformity data in

Figure 8 show a maximum CD of 3.258μm,

a minimum CD of 2.988μm and an average

CD of 3.099μm. Deviation ranges from

-0.20% to 4.12% for an overall uniformity

of 4.32%. The deviation chart shows no

peaking or trending and indicates a stable

exposure field.

Overlay. Overlay accuracy is essential.

We used a 510mm x 515mm glass panel

with a 1.4µm-thick liquid resist as the

overlay test vehicle. The exposure field was

250µm x 250µm. Four shots covered the

entire panel. The test procedure comprised

Figure 6: a) Bossung plot generated from FEM data showing less than 10% deviation over 40μm DOF for 5μm the deposition and patterning of an initial

lines and 70μm DOF for 6μm lines. b) Lower resolution image of 4.5μm, 5μm, 6μm and 7.5μm isolated and layer, followed by deposition and patterning

dense area line/space arrays. c) Higher resolution cross-sectional images of 5μm and 6μm lines in a 10μm-thick of a second, overlying layer. Patterning

dry resist on copper substrate.

45

Chip Scale Review November • December • 2021 [ChipScaleReview.com] 45