Page 24 - Chip Scale Review_November December_2021-digital

P. 24

that matter), systems equipped with camera is not able to do so. to QFPs. This smaller body size results in

side-view cameras are required. An Thermal performance study. As with less area from which to conduct or convect

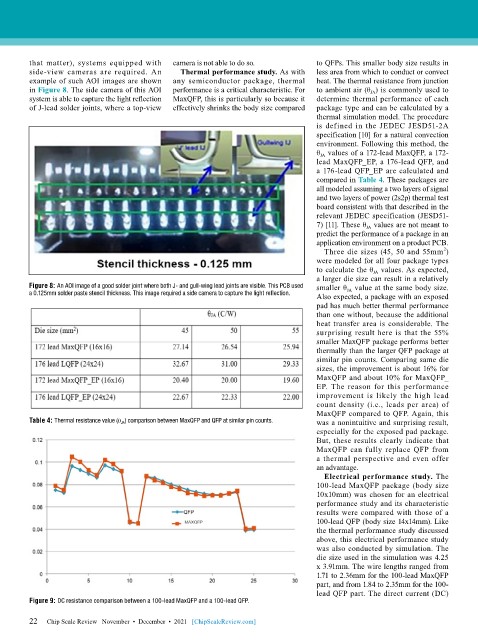

example of such AOI images are shown any semiconductor package, thermal heat. The thermal resistance from junction

in Figure 8. The side camera of this AOI performance is a critical characteristic. For to ambient air (θ JA ) is commonly used to

system is able to capture the light reflection MaxQFP, this is particularly so because it determine thermal performance of each

of J-lead solder joints, where a top-view effectively shrinks the body size compared package type and can be calculated by a

thermal simulation model. The procedure

is defined in the JEDEC JESD51-2A

specification [10] for a natural convection

environment. Following this method, the

θ JA values of a 172-lead MaxQFP, a 172-

lead MaxQFP_EP, a 176-lead QFP, and

a 176-lead QFP_EP are calculated and

compared in Table 4. These packages are

all modeled assuming a two layers of signal

and two layers of power (2s2p) thermal test

board consistent with that described in the

relevant JEDEC specification (JESD51-

7) [11]. These θ JA values are not meant to

predict the performance of a package in an

application environment on a product PCB.

2

Three die sizes (45, 50 and 55mm )

were modeled for all four package types

to calculate the θ JA values. As expected,

a larger die size can result in a relatively

Figure 8: An AOI image of a good solder joint where both J- and gull-wing lead joints are visible. This PCB used smaller θ JA value at the same body size.

a 0.125mm solder paste stencil thickness. This image required a side camera to capture the light reflection. Also expected, a package with an exposed

pad has much better thermal performance

than one without, because the additional

heat transfer area is considerable. The

surprising result here is that the 55%

smaller MaxQFP package performs better

thermally than the larger QFP package at

similar pin counts. Comparing same die

sizes, the improvement is about 16% for

MaxQFP and about 10% for MaxQFP_

EP. The reason for this performance

improvement is likely the high lead

count density (i.e., leads per area) of

MaxQFP compared to QFP. Again, this

Table 4: Thermal resistance value (θ JA ) comparison between MaxQFP and QFP at similar pin counts. was a nonintuitive and surprising result,

especially for the exposed pad package.

But, these results clearly indicate that

MaxQFP can fully replace QFP from

a thermal perspective and even offer

an advantage.

Electrical performance study. The

100-lead MaxQFP package (body size

10x10mm) was chosen for an electrical

performance study and its characteristic

results were compared with those of a

100-lead QFP (body size 14x14mm). Like

the thermal performance study discussed

above, this electrical performance study

was also conducted by simulation. The

die size used in the simulation was 4.25

x 3.91mm. The wire lengths ranged from

1.71 to 2.36mm for the 100-lead MaxQFP

part, and from 1.84 to 2.35mm for the 100-

lead QFP part. The direct current (DC)

Figure 9: DC resistance comparison between a 100-lead MaxQFP and a 100-lead QFP.

22

22 Chip Scale Review November • December • 2021 [ChipScaleReview.com]