Page 21 - Chip Scale Review_November December_2021-digital

P. 21

been collected, which are detailed Technical data summary

below, but are summarized here. As summarized above, the MaxQFP

First, automated optical inspection package was extensively evaluated by

(AOI) has been investigated on several reliability testing, construction analysis,

commercial systems with positive inspectability evaluation, and mechanical,

results. In addition, board-level solder thermal, and electrical simulation. Details

joint reliability (SJR) data meet or of these evaluations follow.

exceed AEC Grade 1 standards. Also, Package reliability. AEC Grade 1

component-level reliability stresses reliability data were collected using a C90

defined by the AEC Q100 standard, nm test vehicle die (with full functionality)

including temperature cycling (TC), in a 172-lead MaxQFP and are summarized

high-temperature storage life (HTSL), in Table 1. This test vehicle passes all

and un-biased humidity accelerated requirements to 2X at a minimum. In an

stress test (uHAST) were conducted— attempt to capture some of the possible

also with positive results. For these manufacturing process variations, four

tests, two different functional die were separate assembly lots were used for

Figure 3: MaxQFP_EP with exposed pad to improve

thermal performance. used, one from the 7 metal layer C40 nm each stress test. Of particular note is the

silicon technology node and one from temperature cycling results, where the

leaded package without an exposed pad. the 4 metal layer C90 nm node. Data in 3,000 cycles passed represent twice the

The thermal performance (e.g., thermal support of the AEC Q006 standard for requirement of the AEC Grade 0 standard.

resistance) of both the MaxQFP and copper wire devices were also collected, This standard is intended for the highest

MaxQFP_EP packages will be detailed and also had positive results. reliability and most extreme automotive

later.

Compared to JEDEC-compliant QFP

packages, MaxQFP offers higher pin

counts at similar body sizes, thereby

enabling reduced consumption of

PCB area. This is a space savings and,

ultimately, cost-saving advantage to

users. For example, the 172-lead MaxQFP

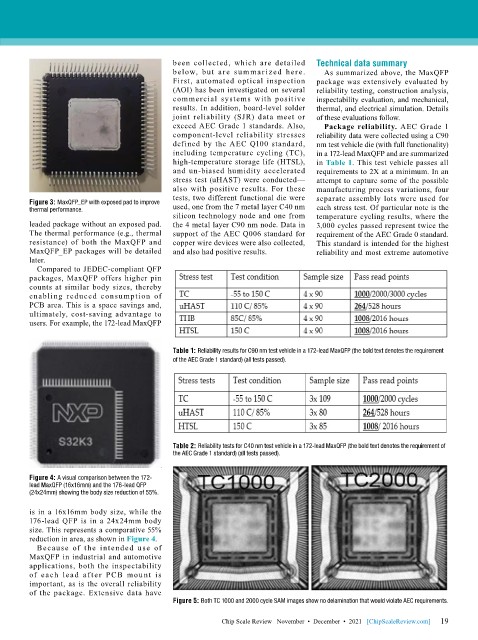

Table 1: Reliability results for C90 nm test vehicle in a 172-lead MaxQFP (the bold text denotes the requirement

of the AEC Grade 1 standard) (all tests passed).

Table 2: Reliability tests for C40 nm test vehicle in a 172-lead MaxQFP (the bold text denotes the requirement of

the AEC Grade 1 standard) (all tests passed).

Figure 4: A visual comparison between the 172-

lead MaxQFP (16x16mm) and the 176-lead QFP

(24x24mm) showing the body size reduction of 55%.

is in a 16x16mm body size, while the

176-lead QFP is in a 24x24mm body

size. This represents a comparative 55%

reduction in area, as shown in Figure 4.

Because of the intended use of

MaxQFP in industrial and automotive

applications, both the inspectability

of each lead af ter PCB mount is

important, as is the overall reliability

of the package. Extensive data have

Figure 5: Both TC 1000 and 2000 cycle SAM images show no delamination that would violate AEC requirements.

19

Chip Scale Review November • December • 2021 [ChipScaleReview.com] 19