Page 23 - Chip Scale Review_November December_2021-digital

P. 23

environments, typically experienced

for electronics in close proximity to the

engine, transmission, or braking systems.

Similar reliability data were also

collected for the C40 nm test vehicle,

again leveraging the 172-lead MaxQFP.

These data are detailed in Table 2. This

test vehicle also passed 2X AEC Grade 1

requirements. As before, multiple assembly

lots were used for each stress test.

In addition to the raw results noted

above, post-stress scanning acoustic

microscopy (SAM) images were taken

to look for any package delamination.

Examples of SAM images of post-TC

1,000- and 2,000-cycle data are shown in

Figure 5. In all cases, no delamination

violating AEC requirements was

observed on the test vehicles. Also, post-

stress decapsulation wire pull and ball

shear tests were performed. All passed

AEC Q006 requirements. Cross-section

scanning electron microscope (SEM)

images were also taken to assure that the

ball bonds have no Cu-Al intermetallic Figure 6: Cross section/SEM image of Cu ball bonds of post-HTSL 2016 hrs showing no sign of Cu-Al IMC

degradation (Figure 6) [1,2] and no Cu degradation and no Cu void formation.

void formation [3,4]. automotive SJR requirement. Design D study. Because the solder joints of J-leads

Board-level solder joint reliability. performs the best—not showing a failure after PCB mounting reside under the

MaxQFP uses the same PCB design rules on the J-leads until 9,791 cycles. It is the package body, they are not inspectable

as a standard 0.5mm pitch QFP—namely recommended PCB footprint design for with legacy AOI systems that only offer

0.1/0.1mm line/space [5]. Therefore, even MaxQFP. a top view. Therefore, for solder joint

though the interstitial pitch of the leads Automated optical inspection system inspection of MaxQFP (or a PLCC, for

is smaller, no finer-pitch (higher cost)

PCB manufacturing is required to design

with MaxQFP. Board-level SJR data were

collected using a daisy chain die in a 172-

lead MaxQFP under the temperature

cycling stress condition of -40 to 125ºC.

Cycling was continued until at least 50%

of the parts failed, thereby enabling a

statistical view of reliability performance.

For this study, four separate PCB board

footprints were designed (Table 3). The Table 3: Four PCB footprints explored for MaxQFP.

general automotive board-level SJR

requirement is to pass 2,000 cycles before

the first fail is detected.

Design A is the baseline design,

which is identical to the existing PCB

Move faster with agile footprint for both QFP gull-wing leads

and plastic-leaded chip carrier (PLCC)

PCB manufacturing J-leads. Design B shares the same lead

length of design A with an increased pad

width. Design C is an aggressive, shorter,

footprint length, but has been eliminated

because it cannot be detected by AOI

systems. Design D is a modified version

of design C, which is inspectable by AOI

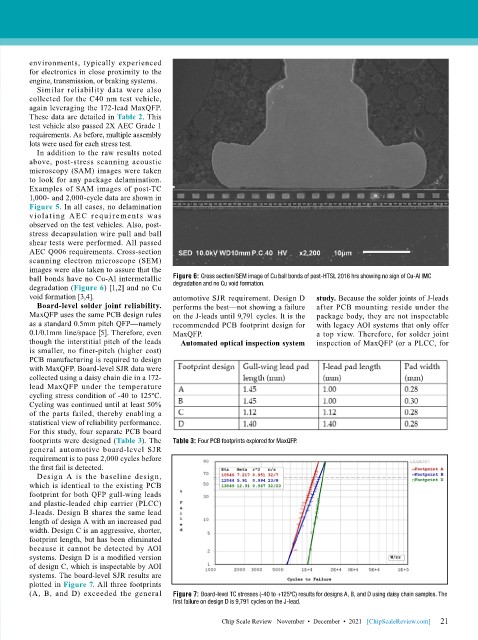

PCB manufacturers that use data to drive decisions move systems. The board-level SJR results are

faster than competitors and reduce production costs. plotted in Figure 7. All three footprints

Learn how to adopt advanced manufacturing strategies to (A, B, and D) exceeded the general Figure 7: Board-level TC stresses (-40 to +125ºC) results for designs A, B, and D using daisy chain samples. The

transform complex data into a unified digital thread. Scan for first failure on design D is 9,791 cycles on the J-lead.

the eBook

21

Chip Scale Review November • December • 2021 [ChipScaleReview.com] 21