Page 20 - Chip Scale Review_November December_2021-digital

P. 20

A new, higher density QFP

By Chu-Chung (Stephen) Lee, Yao Jinzhong, Glenn G. Daves [NXP Semiconductors N.V.]

This technical article (part 2) is a continuation of the Emerging Technologies column entitled, “A new, higher density QFP”

in the September • October 2021 issue of Chip Scale Review.

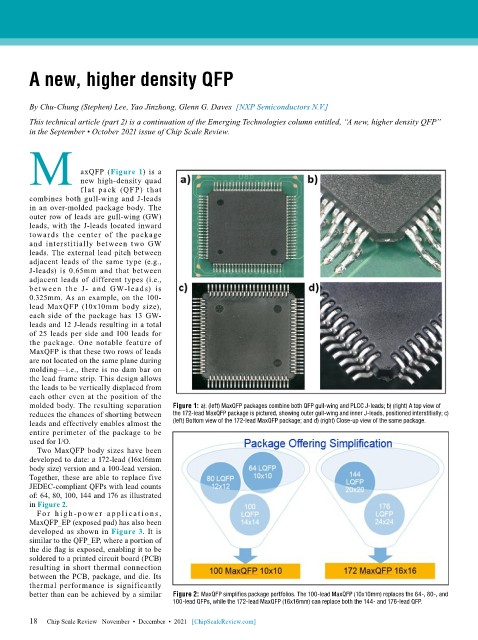

M axQFP (Figure 1) is a

new high-density quad

f lat pack (QFP) that

combines both gull-wing and J-leads

in an over-molded package body. The

outer row of leads are gull-wing (GW)

leads, with the J-leads located inward

towards the center of the package

and interstitially between two GW

leads. The external lead pitch between

adjacent leads of the same type (e.g.,

J-leads) is 0.65mm and that between

adjacent leads of different types (i.e.,

bet ween the J- and GW-leads) is

0.325mm. As an example, on the 100-

lead MaxQFP (10x10mm body size),

each side of the package has 13 GW-

leads and 12 J-leads resulting in a total

of 25 leads per side and 100 leads for

the package. One notable feature of

MaxQFP is that these two rows of leads

are not located on the same plane during

molding—i.e., there is no dam bar on

the lead frame strip. This design allows

the leads to be vertically displaced from

each other even at the position of the

molded body. The resulting separation Figure 1: a): (left) MaxQFP packages combine both QFP gull-wing and PLCC J-leads; b) (right) A top view of

reduces the chances of shorting between the 172-lead MaxQFP package is pictured, showing outer gull-wing and inner J-leads, positioned interstitially; c)

leads and effectively enables almost the (left) Bottom view of the 172-lead MaxQFP package; and d) (right) Close-up view of the same package.

entire perimeter of the package to be

used for I/O.

Two MaxQFP body sizes have been

developed to date: a 172-lead (16x16mm

body size) version and a 100-lead version.

Together, these are able to replace five

JEDEC-compliant QFPs with lead counts

of: 64, 80, 100, 144 and 176 as illustrated

in Figure 2.

Fo r h ig h - p owe r a p pl ic a t io n s ,

MaxQFP_EP (exposed pad) has also been

developed as shown in Figure 3. It is

similar to the QFP_EP, where a portion of

the die flag is exposed, enabling it to be

soldered to a printed circuit board (PCB)

resulting in short thermal connection

between the PCB, package, and die. Its

thermal performance is significantly

better than can be achieved by a similar Figure 2: MaxQFP simplifies package portfolios. The 100-lead MaxQFP (10x10mm) replaces the 64-, 80-, and

100-lead QFPs, while the 172-lead MaxQFP (16x16mm) can replace both the 144- and 176-lead QFP.

18 Chip Scale Review November • December • 2021 [ChipScaleReview.com]

18