Page 15 - Chip Scale Review_November December_2021-digital

P. 15

vias (TSVs) was developed to handle high-bandwidth memory

(HBM) devices that have multiple 128-bit data channels—

far too many for perimeter wire bond pads. HBM chips are

stacked with each chip mounted directly over a lower chip.

Figure 6 depicts a four-memory chip, staggered-chip stack

with the chips wire bonded to an organic substrate (top)

and a four-memory chip stack on a processor or interface

chip with TSVs in the lower chips and micro-solder bumps

interconnecting the chips. 3D chip stacking can increase

circuit density by a factor of 2X to 10X, depending on how

many chips are stacked. It also lowers the interconnect

parasitics from the memory chips to the processor chip

by more than an order of magnitude. 3D chip stacking is

Figure 5: FOPLP versus fan-out FOWLP: a) (left) 450mm x 550mm panel format; generally limited to memory chips where only one chip in the

and b) (right) 300mm diameter wafer format. stack is active at a time. 3D chip stacking can have a higher

level processing of fan-out devices with their larger format yield loss as the chips have only been wafer tested. This is

panels will yield significant cost reductions over wafer-level similar to the yield issues in ECPs noted above.

processing because of the larger panel area and the lower

equipment costs [4]. A wafer-level process on a 300mm line Package-on-package (PoP) stacking

2

has about 70Kmm of processing area while a 450mm by For non-memory 3D applications such as mixed memory

2

550mm panel has about 240Kmm of processing area—a and processor applications, package-on-package (PoP)

3.5 to 1 increase in processing area as depicted in Figure 5. technologies were developed. In this approach, single chips

FOPLPs are electrically, thermally and physically identical and chip stacks can be packaged in a stackable chip carrier

to FOWLPs. and two packages can be directly stacked on each other

using BGA solder attach. Two typical PoPs are depicted in

3D-chip stacking Figure 7. A lower performance PoP configuration is depicted

In order to increase the memory capacity per unit area and

to minimize the physical distance from the memory chips to

the processor chip, semiconductor companies and assemblers

developed a number of chip stacking technologies. In the

early chip stacking approaches, multiple bare memory chips

with perimeter wire bond pads were stacked one on top of

another forming a stack of two, four, or more chips. In one

approach, chips were designed with all I/Os on one chip edge.

Chips were then mounted with every other chip offset on one

side and then the other with all I/O pads exposed. Low-profile

wire bonds connected each chip pad either to a lower chip’s

pad or to the package substrate. For higher I/O count chips,

a spacer would be mounted between each chip allowing wire

bonding on all four sides. 3D stacking with through-silicon

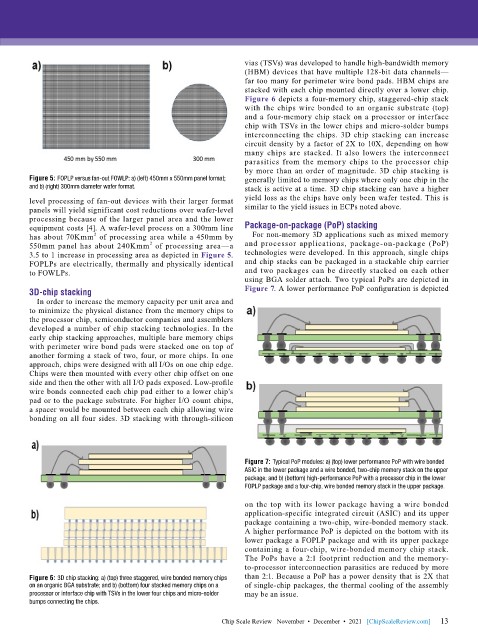

Figure 7: Typical PoP modules: a) (top) lower performance PoP with wire bonded

ASIC in the lower package and a wire bonded, two-chip memory stack on the upper

package; and b) (bottom) high-performance PoP with a processor chip in the lower

FOPLP package and a four-chip, wire bonded memory stack in the upper package.

on the top with its lower package having a wire bonded

application-specific integrated circuit (ASIC) and its upper

package containing a two-chip, wire-bonded memory stack.

A higher performance PoP is depicted on the bottom with its

lower package a FOPLP package and with its upper package

containing a four-chip, wire-bonded memory chip stack.

The PoPs have a 2:1 footprint reduction and the memory-

to-processor interconnection parasitics are reduced by more

Figure 6: 3D chip stacking: a) (top) three staggered, wire bonded memory chips than 2:1. Because a PoP has a power density that is 2X that

on an organic BGA substrate; and b) (bottom) four stacked memory chips on a of single-chip packages, the thermal cooling of the assembly

processor or interface chip with TSVs in the lower four chips and micro-solder may be an issue.

bumps connecting the chips.

13

Chip Scale Review November • December • 2021 [ChipScaleReview.com] 13