Page 45 - ChipScale_Jan-Feb_2020-digital

P. 45

Creating Safe © 2017 Brewer Science, Inc.

Environments

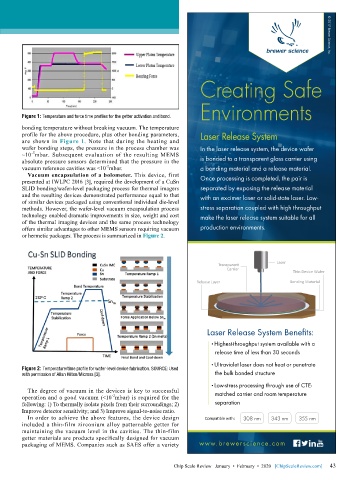

Figure 1: Temperature and force time profiles for the getter activation and bond.

bonding temperature without breaking vacuum. The temperature

profile for the above procedure, plus other bonding parameters, Laser Release System

are shown in Figure 1. Note that during the heating and

wafer bonding steps, the pressure in the process chamber was In the laser release system, the device wafer

-5

~10 mbar. Subsequent evaluation of the resulting MEMS

absolute pressure sensors determined that the pressure in the is bonded to a transparent glass carrier using

-2

vacuum reference cavities was <10 mbar. a bonding material and a release material.

Vacuum encapsulation of a bolometer. This device, first

presented at IWLPC 2016 [3], required the development of a CuSn Once processing is completed, the pair is

SLID bonding/wafer-level packaging process for thermal imagers separated by exposing the release material

and the resulting devices demonstrated performance equal to that with an excimer laser or solid-state laser. Low-

of similar devices packaged using conventional individual die-level

methods. However, the wafer-level vacuum encapsulation process stress separation coupled with high throughput

technology enabled dramatic improvements in size, weight and cost make the laser release system suitable for all

of the thermal imaging devices and the same process technology

offers similar advantages to other MEMS sensors requiring vacuum production environments.

or hermetic packages. The process is summarized in Figure 2.

Laser

Transparent

Carrier

Thin Device Wafer

Release Layer Bonding Material

Laser Release System Benefits:

•Highest-throughput system available with a

release time of less than 30 seconds

•Ultraviolet laser does not heat or penetrate

Figure 2: Temperature/time profile for wafer-level device fabrication. SOURCE: Used

with permission of Allan Hilton/Micross [3]. the bulk bonded structure

•Low-stress processing through use of CTE-

The degree of vacuum in the devices is key to successful

-2

operation and a good vacuum (<10 mbar) is required for the matched carrier and room temperature

following: 1) To thermally isolate pixels from their surroundings; 2) separation

Improve detector sensitivity; and 3) Improve signal-to-noise ratio.

In order to achieve the above features, the device design Compatible with: 308 nm 343 nm 355 nm

included a thin-film zirconium alloy patternable getter for

maintaining the vacuum level in the cavities. The thin-film

getter materials are products specifically designed for vacuum

packaging of MEMS. Companies such as SAES offer a variety www.brewerscience.com

43

Chip Scale Review January • February • 2020 [ChipScaleReview.com] 43