Page 29 - Chip Scale Review_May June_2021-digital

P. 29

liquid flow to and from the To achieve the desired thermal dissipation

DUT vertically, a liquid- at test, while providing a reliable solution

based thermal head can for their users, engineering teams must

provide significant cooling work closely with their socket vendors.

while staying inside the x/ Thermal requirements must be clearly

y profile across the PCB documented, and detailed simulations of

compared to an air-based mechanical, electrical – and now thermal –

solution. Such a liquid- performance must be completed. For many

cooled thermal lid will 300W – 500W devices, both air and liquid

have hoses attached that cooling can be considered. The choice of

must be managed, but these which solution to pursue will depend very

can be much lighter and heavily on the requirements of the end

easier to handle than a heat users. Test engineering hardware teams

pipe design with a large, must stay well informed about their users’

heavy heat sink attached. requirements and make critical tradeoffs

Management of the liquid when providing design guidance to their

hoses has not proven to be socket vendors. In the world of these

a major issue – in general, power-hungry chips, effective test socket

the hoses are lightweight thermal design is a critical element to

and flexible, so a simple ensure on-time design release.

cable-type management

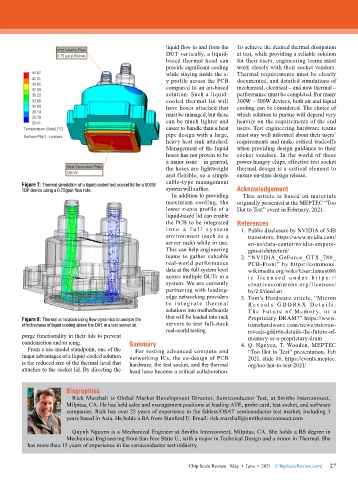

Figure 7: Thermal simulation of a liquid cooled test socket lid for a 500W

TDP device using a 0.75gpm flow rate. system will suffice. Acknowledgement

In addition to providing This article is based on materials

maximum cooling, the originally presented at the MEPTEC “Too

lower z-axis profile of a Hot to Test” event in February, 2021.

liquid-based lid can enable

the PCB to be integrated References

i n t o a f u l l s y s t e m 1. Public disclosure by NVIDIA of 54B

environment (such as a transistors, https://www.nvidia.com/

server rack) while in use. en-us/data-center/nvidia-ampere-

This can help engineering gpu-architecture/

teams to gather valuable 2. “NVIDIA_GeForce_GTX_780_

real-world performance PCB-Front” by https://commons.

data at the full system level wikimedia.org/wiki/User:James086

across multiple DUTs in a i s l i c e n s e d u n d e r h t t p s :/ /

system. We are currently creativecommons.org/licenses/

partnering with leading- by/2.0/deed.en

edge networking providers 3. Tom’s Hardware article, “Micron

to i nteg r ate t her mal R e v e a l s G D DR 6 X D e t a i l s :

solutions into motherboards T he Fut u re of Memor y, or a

that will be loaded into rack Proprietary DRAM?” https://www.

Figure 8: Thermal simulation using flow dynamics to analyze the

effectiveness of liquid cooling above the DUT in a test socket lid. servers to test full-stack tomshardware.com/news/micron-

real-world testing. reveals-gddr6x-details-the-future-of-

purge functionality in their lids to prevent memory-or-a-proprietary-dram

condensation and/or icing. Summary 4. Q. Nguyen, T. Wooden, MEPTEC

From a use-model standpoint, one of the For testing advanced compute and “Too Hot to Test” presentation, Feb

major advantages of a liquid-cooled solution networking ICs, the co-design of PCB 2021, slide #6, https://events.meptec.

is the reduced size of the thermal head that hardware, the test socket, and the thermal org/too-hot-to-test-2021/

attaches to the socket lid. By directing the head have become a critical collaboration.

Biographies

Rick Marshall is Global Market Development Director, Semiconductor Test, at Smiths Interconnect,

Milpitas, CA. He has held sales and management positions at leading ATE, probe card, test socket, and software

companies. Rick has over 25 years of experience in the fabless/OSAT semiconductor test market, including 3

years based in Asia. He holds a BA from Stanford U. Email: rick.marshall@smithsinterconnect.com

Quynh Nguyen is a Mechanical Engineer at Smiths Interconnect, Milpitas, CA. She holds a BS degree in

Mechanical Engineering from San Jose State U., with a major in Technical Design and a minor in Thermal. She

has more than 15 years of experience in the semiconductor test industry.

27

Chip Scale Review May • June • 2021 [ChipScaleReview.com] 27