Page 25 - Chip Scale Review_May June_2021-digital

P. 25

Cooling high-wattage digital ICs for socketed

system-level test

By Rick Marshall, Quynh Nguyen, Tim Wooden, Jiachun (Frank) Zhou [Smiths Interconnect]

M odern computing and are preferred because

networking applications

mechanical durability.

are driving a new class they deliver greater

of digital integrated circuits (ICs) that have SLT test environments

enormous power dissipation requirements. differ from ATE-based

Built exclusively on the advanced 7nm and setups in many critical

5nm wafer fabrication nodes, these devices ways. These differences

have massive transistor counts, already require an entirely Table 1: Die size and transistor count trends for flagship GPUs from the

exceeding 50 billion in the newest designs n e w s e t of d e sig n 28nm process node to the state-of-the-art 7nm node.

[1]. Designed to handle extreme tasks such as considerations for a test

graphics processing, crypto-mining, artificial engineering group and

intelligence (AI), and network switching, its socket vendor. Critical

these chips prioritize “performance at all trade-offs must be made

costs” such that reducing IC power draw is to balance the electrical

not a consideration. As the transistor density test requirements against

at these nodes increases, power density the need for a reliable,

follows suit (Table 1, Figure 1). Chips with adequately cooled test

sustained power draws over 300W of thermal socket. Key among these

design power (TDP) are now common, with tradeoffs is deciding

advanced designs in the 400W to 650W whether to pursue an air-

range. In the second half of 2021, multiple cooled thermal solution,

designs will be released that will average or to make use of liquid

800W TDP, with peak consumption expected cooling.

to exceed 1,000W. These large power

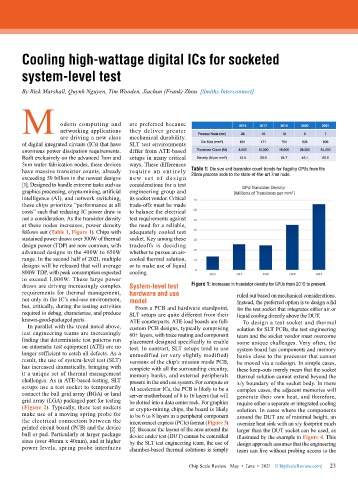

draws are driving increasingly complex System-level test Figure 1: Increases in transistor density for GPUs from 2015 to present.

requirements for thermal management, hardware and use ruled out based on mechanical considerations.

not only in the IC’s end-use environment, model Instead, the preferred option is to design a lid

but, critically, during the testing activities From a PCB and hardware standpoint, for the test socket that integrates either air or

required to debug, characterize, and produce SLT setups are quite different from their liquid cooling directly above the DUT.

known-good-packaged parts. ATE counterparts. ATE load boards are full- To design a test socket and thermal

In parallel with the trend noted above, custom PCB designs, typically comprising solution for SLT PCBs, the test engineering

test engineering teams are increasingly 60+ layers, with trace routing and component team and the socket vendor must overcome

finding that deterministic test patterns run placement designed specifically to enable some unique challenges. Very often, the

on automatic test equipment (ATE) are no test. In contrast, SLT setups tend to use system board has components and memory

longer sufficient to catch all defects. As a unmodified (or very slightly modified) banks close to the processor that cannot

result, the use of system-level test (SLT) versions of the chip’s mission mode PCB, be moved via a redesign. In simple cases,

has increased dramatically, bringing with complete with all the surrounding circuitry, these keep-outs merely mean that the socket

it a unique set of thermal management memory banks, and external peripherals thermal solution cannot extend beyond the

challenges. As in ATE-based testing, SLT present in the end use system. For compute or x/y boundary of the socket body. In more

setups use a test socket to temporarily AI accelerator ICs, the PCB is likely to be a complex cases, the adjacent memories will

connect the ball grid array (BGA) or land server motherboard of 8 to 16 layers that will generate their own heat, and therefore,

grid array (LGA) packaged part for testing be slotted into a data center rack. For graphics require either a separate or integrated cooling

(Figure 2). Typically, these test sockets or crypto-mining chips, the board is likely solution. In cases where the components

make use of a moving spring probe for to be 6 to 8 layers in a peripheral component around the DUT are of minimal height, an

the electrical connection between the interconnect express (PCIe) format (Figure 3) oversize heat sink with an x/y footprint much

printed circuit board (PCB) and the device [2]. Because the layout of the area around the larger than the DUT socket can be used, as

ball or pad. Particularly at larger package device under test (DUT) cannot be controlled illustrated by the example in Figure 4. This

sizes (over 40mm x 40mm), and at higher by the SLT test engineering team, the use of design approach assumes that the engineering

power levels, spring probe interfaces chamber-based thermal solutions is simply team can live without probing access to the

23

Chip Scale Review May • June • 2021 [ChipScaleReview.com] 23