Page 28 - Chip Scale Review_May June_2021-digital

P. 28

0.1°C/W range, heat sinks can achieve 350W TDP, the size and

case and junction temperatures (Tc and weight of the heat sink

Tj, respectively) well inside a typical apparatus can become

target range of 75°C - 100°C. For many quite substantial. So,

of today’s 50mm x 50mm to 70mm a compromise must

x 70mm packages, this approach can be st r uck bet ween

still be effective (Figure 5). Because r e li a b i li t y a n d

these heat sinks are inexpensive, easy ergonomics.

to manufacture, reliable, and simple to

use, they are an attractive choice for the Liquid-cooled

test engineer. Additionally, there are no solutions

moving parts, no settings to adjust, and for compact

no fan noise – all features that make them performance

popular with end-users. Compared to solid

With today’s die scaling capabilities at metal or heat pipe-based

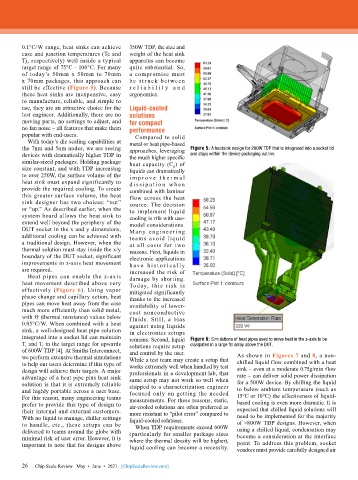

the 7nm and 5nm nodes, we are seeing approaches, leveraging Figure 5: A heatsink design for 200W TDP that is integrated into a socket lid

devices with dramatically higher TDP in the much higher specific and stays within the device packaging outline.

similar-sized packages. Holding package heat capacity (C p ) of

size constant, and with TDP increasing liquids can dramatically

to over 250W, the surface volume of the i m p r o v e t h e r m a l

heat sink must expand significantly to d i s s i p a t i on w h e n

provide the required cooling. To create combined with laminar

this greater surface volume, the heat flow across the heat

sink designer has two choices: “out” source. The decision

or “up.” As described earlier, when the to implement liquid

system board allows the heat sink to cooling is rife with use-

extend well beyond the periphery of the model considerations.

DUT socket in the x and y dimensions, Ma ny eng i neer i ng

additional cooling can be achieved with teams avoid liquid

a traditional design. However, when the at all costs for two

thermal solution must stay inside the x/y reasons. First, liquids in

boundary of the DUT socket, significant electronic applications

improvements in z-axis heat movement h a v e h i s t o r i c a l l y

are required. increased the risk of

Heat pipes can enable the z-axis damage by shorting.

heat movement described above very Today, this risk is

effectively (Figure 6). Using vapor mitigated significantly

phase change and capillary action, heat thanks to the increased

pipes can move heat away from the case availability of lower-

much more efficiently than solid metal, cost nonconductive

with ϴ (thermal resistance) values below f luids. Still, a bias

0.05°C/W. When combined with a heat against using liquids

sink, a well-designed heat pipe solution in electronics setups

integrated into a socket lid can maintain remains. Second, liquid Figure 6: Simulations of heat pipes used to move heat in the z-axis to be

T c and T j in the target range for upwards solutions require setup dissipated in a large fin array above the DUT.

of 600W TDP [4]. At Smiths Interconnect, and control by the user.

we perform extensive thermal simulations While a test team may create a setup that As shown in Figures 7 and 8, a non-

to help our users determine if this type of works extremely well when handled by test chilled liquid flow combined with a heat

design will achieve their targets. A major professionals in a development lab, that sink – even at a moderate 0.75g/min flow

advantage of a heat pipe plus heat sink same setup may not work so well when rate – can deliver solid power dissipation

solution is that it is extremely reliable shipped to a characterization engineer for a 500W device. By chilling the liquid

and highly portable across a user base. focused only on getting the needed to below ambient temperature (such as

For this reason, many engineering teams measurements. For these reasons, static, 15°C or 10°C) the effectiveness of liquid-

prefer to provide this type of design to air-cooled solutions are often preferred as based cooling is even more dramatic. It is

their internal and external customers. more resistant to “pilot error” compared to expected that chilled liquid solutions will

With no liquid to manage, chiller settings liquid-cooled solutions. need to be implemented for the majority

to handle, etc., these setups can be When TDP requirements exceed 600W of >800W TDP designs. However, when

delivered to teams around the globe with (particularly for smaller package sizes using a chilled liquid, condensation may

minimal risk of user error. However, it is where the thermal density will be higher), become a consideration at the interface

important to note that for designs above liquid cooling can become a necessity. point. To address this problem, socket

vendors must provide carefully designed air

26 Chip Scale Review May • June • 2021 [ChipScaleReview.com]

26