Page 32 - ChipScale_Jan-Feb_2021-digital

P. 32

backgrind equipment or testers/handlers.

For example, one could continue utilizing

200mm or 300mm tooling for the ball

mount process post-panel singulation to

minimize capital expenditure. A slight

modification to the panel chuck to fit

the singulated panel geometry would be

required, along with the ball dispense

process. However, some considerations

need to be taken into account for

maximizing the GDPP. There is a tradeoff

from segmenting the 600mm x 600mm

panel into nine 200mm segments versus

four 300mm segments.

Referencing Table 3, a 5mm x 5mm

single-die package was used as a test

vehicle. The total usable area loss was

calculated by subtracting the sum of the

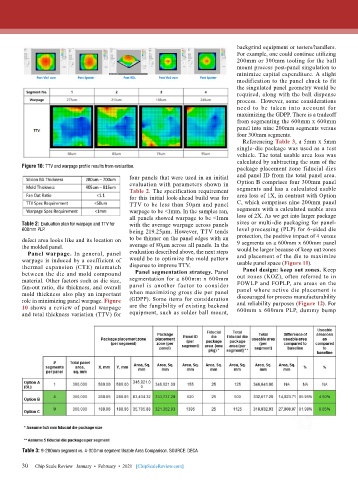

Figure 10: TTV and warpage profile results from evaluation. package placement zone fiducial dies

four panels that were used in an initial and panel ID from the total panel area.

evaluation with parameters shown in Option B comprises four 300mm panel

Table 2. The specification requirement segments and has a calculated usable

for this initial look-ahead build was for area loss of 1X, in contrast with Option

TTV to be less than 50µm and panel C, which comprises nine 200mm panel

warpage to be <1mm. In the samples ran, segments with a calculated usable area

all panels showed warpage to be <1mm loss of 2X. As we get into larger package

Table 2: Evaluation plan for warpage and TTV for with the average warpage across panels sizes or multi-die packaging for panel-

600mm PLP. being 219.25µm. However, TTV tends level processing (PLP) for 6-sided die

defect area looks like and its location on to be thinner on the panel edges with an protection, the positive impact of 4 versus

9 segments on a 600mm x 600mm panel

the molded panel. average of 80µm across all panels. In the would be larger because of keep out zones

Panel warpage. In general, panel evaluation described above, the next steps and placement of the die to maximize

warpage is induced by a coefficient of would be to optimize the mold pattern usable panel space (Figure 11).

thermal expansion (CTE) mismatch dispense to improve TTV. Panel design: keep out zones. Keep

between the die and mold compound Panel segmentation strategy. Panel out zones (KOZ), often referred to in

material. Other factors such as die size, segmentation for a 600mm x 600mm FOWLP and FOPLP, are areas on the

fan-out ratio, die thickness, and overall panel is another factor to consider panel where active die placement is

mold thickness also play an important when maximizing gross die per panel discouraged for process manufacturability

role in minimizing panel warpage. Figure (GDPP). Some items for consideration and reliability purposes (Figure 12). For

10 shows a review of panel warpage are the fungibility of existing backend 600mm x 600mm PLP, dummy bump

and total thickness variation (TTV) for equipment, such as solder ball mount,

Table 3: 9-200mm segment vs. 4-300mm segment Usable Area Comparison. SOURCE: DECA

30

30 Chip Scale Review January • February • 2021 [ChipScaleReview.com]