Page 31 - ChipScale_Jan-Feb_2021-digital

P. 31

to compensate for minor die shifts during

RDL patterning will also contribute to

overall panel yield.

CSAM inspection: mold voids

detection. Mold voids can occur because

of short gel time, short spiral flow length

of the mold compound, contamination on

the interface between silicon and mold

compound material, or an un-optimized

mold dispense profile and parameters,

to name a few causes. In the example

from Figure 8b, mold voids are normally

detected with a CSAM metrology tool

because a standard microscope will

not be able to detect voids at the mold

compound to the Si interface layer

(Figure 8a). Figure 8c confirms post-

Cu stud top grind that mold voids were

Figure 6: Die shift illustration from chip attach to post-mold cure.

custom adaptive pattern to each panel [1].

Utilizing this photolithography process

helps with mitigating issues encountered

during die shift (X, Y, Ɵ).

Key challenges in 600mm panel

processing

Some of the key challenges in 600mm

x 600mm PLP are die shift during the

panelization process, warpage control,

mold thickness variation, C-mode

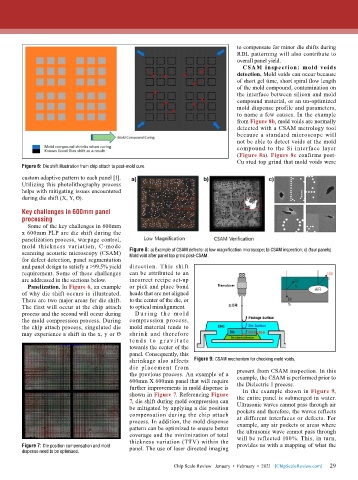

scanning acoustic microscopy (CSAM) Figure 8: a) Example of CSAM defects: a) low magnification microscope; b) CSAM inspection; c) (four panels)

Mold void after panel top grind post-CSAM.

for defect detection, panel segmentation

and panel design to satisfy a >99.5% yield direction. This shift

requirement. Some of these challenges can be attributed to an

are addressed in the sections below. incorrect recipe set-up

Panelization. In Figure 6, an example or pick and place bond

of why die shift occurs is illustrated. heads that are not aligned

There are two major areas for die shift. to the center of the die, or

The first will occur at the chip attach to optical misalignment.

process and the second will occur during D u r i n g t h e m ol d

the mold compression process. During compression process,

the chip attach process, singulated die mold material tends to

may experience a shift in the x, y or Ɵ shrink and therefore

te n d s t o g r a v i t a te

towards the center of the

panel. Consequently, this

shrinkage also affects Figure 9: CSAM mechanism for checking mold voids.

die placement f rom present from CSAM inspection. In this

the previous process. An example of a example, the CSAM is performed prior to

600mm X 600mm panel that will require the Dielectric 1 process.

further improvements in mold dispense is In the example shown in Figure 9,

shown in Figure 7. Referencing Figure the entire panel is submerged in water.

7, die shift during mold compression can Ultrasonic waves cannot pass through air

be mitigated by applying a die position pockets and therefore, the waves reflects

compensation during the chip attach at different interfaces or defects. For

process. In addition, the mold dispense example, any air pockets or areas where

pattern can be optimized to ensure better the ultrasonic wave cannot pass through

coverage and the minimization of total will be reflected 100%. This, in turn,

thickness variation (TTV) within the

Figure 7: Die position compensation and mold panel. The use of laser directed imaging provides us with a mapping of what the

dispense need to be optimized.

29

Chip Scale Review January • February • 2021 [ChipScaleReview.com] 29