Page 24 - ChipScale_Nov-Dec_2020-digital

P. 24

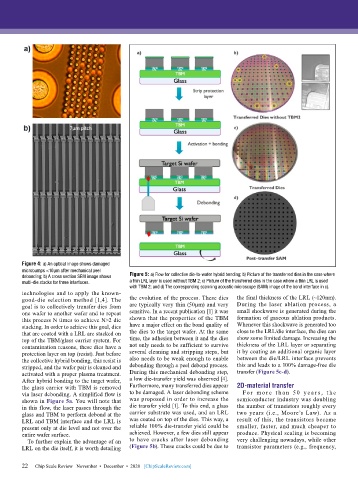

Figure 4: a) An optical image shows damaged

microbumps <10µm after mechanical peel

debonding; b) A cross section SEM image shows Figure 5: a) Flow for collective die-to-wafer hybrid bonding; b) Picture of the transferred dies in the case where

multi-die stacks for three interfaces. a thin LRL layer is used without TBM 2; c) Picture of the transferred dies in the case where a thin LRL is used

with TBM 2; and d) The corresponding scanning acoustic microscope (SAM) image of the bond interface in c).

technologies and to apply the known-

good-die selection method [1,4]. The the evolution of the process. These dies the final thickness of the LRL (~120nm).

goal is to collectively transfer dies from are typically very thin (50µm) and very During the laser ablation process, a

one wafer to another wafer and to repeat sensitive. In a recent publication [1] it was small shockwave is generated during the

this process N times to achieve N>2 die shown that the properties of the TBM formation of gaseous ablation products.

stacking. In order to achieve this goal, dies have a major effect on the bond quality of Whenever this shockwave is generated too

that are coated with a LRL are stacked on the dies to the target wafer. At the same close to the LRL/die interface, the dies can

top of the TBM/glass carrier system. For time, the adhesion between it and the dies show some limited damage. Increasing the

contamination reasons, these dies have a not only needs to be sufficient to survive thickness of the LRL layer or separating

protection layer on top (resist). Just before several cleaning and stripping steps, but it by coating an additional organic layer

the collective hybrid bonding, this resist is also needs to be weak enough to enable between the die/LRL interface prevents

stripped, and the wafer pair is cleaned and debonding through a peel debond process. this and leads to a 100% damage-free die

activated with a proper plasma treatment. During this mechanical debonding step, transfer (Figure 5c-d).

After hybrid bonding to the target wafer, a low die-transfer yield was observed [4].

the glass carrier with TBM is removed Furthermore, many transferred dies appear 2D-material transfer

via laser debonding. A simplified flow is to be damaged. A laser debonding scheme Fo r m o r e t h a n 5 0 y e a r s , t h e

shown in Figure 5a. You will note that was proposed in order to increase the semiconductor industry was doubling

in this flow, the laser passes through the die transfer yield [1]. To this end, a glass the number of transistors roughly every

glass and TBM to perform debond at the carrier substrate was used, and an LRL two years (i.e., Moore’s Law). As a

LRL and TBM interface and the LRL is was coated on top of the dies. This way, a result of this, the transistors became

present only at die level and not over the reliable 100% die-transfer yield could be smaller, faster, and much cheaper to

entire wafer surface. achieved. However, a few dies still appear produce. Physical scaling is becoming

To further explain the advantage of an to have cracks after laser debonding very challenging nowadays, while other

LRL on the die itself, it is worth detailing (Figure 5b). These cracks could be due to transistor parameters (e.g., frequency,

22 Chip Scale Review November • December • 2020 [ChipScaleReview.com]

22