Page 22 - ChipScale_Nov-Dec_2020-digital

P. 22

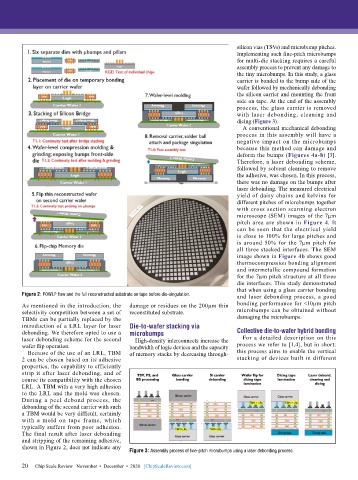

silicon vias (TSVs) and microbump pitches.

Implementing such fine-pitch microbumps

for multi-die stacking requires a careful

assembly process to prevent any damage to

the tiny microbumps. In this study, a glass

carrier is bonded to the bump side of the

wafer followed by mechanically debonding

the silicon carrier and mounting the front

side on tape. At the end of the assembly

process, the glass carrier is removed

with laser debonding, cleaning and

dicing (Figure 3).

A conventional mechanical debonding

process in this assembly will have a

negative impact on the microbumps

because this method can damage and

deform the bumps (Figures 4a-b) [3].

Therefore, a laser debonding scheme,

followed by solvent cleaning to remove

the adhesive, was chosen. In this process,

there was no damage on the bumps after

laser debonding. The measured electrical

yield of daisy chains and kelvins for

different pitches of microbumps together

with cross section scanning electron

microscope (SEM) images of the 7µm

pitch area are shown in Figure 4. It

can be seen that the electrical yield

is close to 100% for large pitches and

is around 50% for the 7µm pitch for

all three stacked interfaces. The SEM

image shown in Figure 4b shows good

thermocompression bonding alignment

and intermetallic compound formation

for the 7µm pitch structure at all three

die interfaces. This study demonstrated

that when using a glass carrier bonding

Figure 2: FOWLP flow and the full reconstructed substrate on tape before die-singulation. and laser debonding process, a good

As mentioned in the introduction, the damage or residues on the 200µm thin bonding performance for <10µm pitch

selectivity competition between a set of reconstituted substrate. microbumps can be obtained without

TBMs can be partially replaced by the damaging the microbumps.

introduction of a LRL layer for laser Die-to-wafer stacking via

debonding. We therefore opted to use a microbumps Collective die-to-wafer hybrid bonding

laser debonding scheme for the second High-density interconnects increase the For a detailed description on this

wafer flip operation. bandwidth of logic devices and the capacity process we refer to [1,4], but in short:

Because of the use of an LRL, TBM of memory stacks by decreasing through- this process aims to enable the vertical

2 can be chosen based on its adhesive stacking of devices built in different

properties, the capability to efficiently

strip it after laser debonding, and of

course its compatibility with the chosen

LRL. A TBM with a very high adhesion

to the LRL and the mold was chosen.

During a peel debond process, the

debonding of the second carrier with such

a TBM would be very difficult, certainly

with a mold on tape frame, which

typically suffers from poor adhesion.

The final result after laser debonding

and stripping of the remaining adhesive,

shown in Figure 2, does not indicate any

Figure 3: Assembly process of fine-pitch microbumps using a laser debonding process.

20

20 Chip Scale Review November • December • 2020 [ChipScaleReview.com]