Page 35 - ChipScale_Sep-Oct_2020-digital

P. 35

defect modes and determines pass

(overkill) or reject. For an example such

as FM (particle), other defect modes of

stain, fiber, and crack can easily cause

overkill and underkill situations.

C o m b i ne d s e g me n t at i o n a n d

classification algorithms in series first

checks all rejects (by machine vision)

one more time based on customer

criteria (segmentation trained model)

and finally decides on whether the

classification should be a true reject

or pass (overkill) based on defect

classes (classification trained model)

and the customer specification. The AI

inspection progress using combined

algorithms is shown in Figure 3. As

an example, for the bump damage case

study, machine vision determines the

pass units. Reject bumps are inspected

by the segmentation algorithm, followed

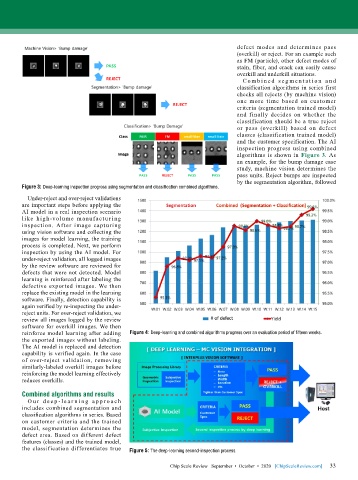

Figure 3: Deep-learning inspection progress using segmentation and classification combined algorithms.

Under-reject and over-reject validations

are important steps before applying the

AI model in a real inspection scenario

li ke high-volu me manufact u r i ng

inspection. After image capturing

using vision software and collecting the

images for model learning, the training

process is completed. Next, we perform

inspection by using the AI model. For

under-reject validation, all logged images

by the review software are reviewed for

defects that were not detected. Model

learning is reinforced after labeling the

defective exported images. We then

replace the existing model in the learning

software. Finally, detection capability is

again verified by re-inspecting the under-

reject units. For over-reject validation, we

review all images logged by the review

software for overkill images. We then

reinforce model learning after adding Figure 4: Deep-learning and combined algorithms progress over an evaluation period of fifteen weeks.

the exported images without labeling.

The AI model is replaced and detection

capability is verified again. In the case

of over-reject validation, removing

similarly-labeled overkill images before

reinforcing the model learning effectively

reduces overkills.

Combined algorithms and results

O u r d e e p - l e a r n i ng a p p r o a c h

includes combined segmentation and

classification algorithms in series. Based

on customer criteria and the trained

model, segmentation determines the

defect area. Based on different defect

features (classes) and the trained model,

the classification differentiates true Figure 5: The deep-learning second-inspection process.

33

Chip Scale Review September • October • 2020 [ChipScaleReview.com] 33